Why Choose a Universal Tensile Testing Machine for Material Testing?

In the world of material testing, accuracy and reliability are vital. A universal tensile testing machine stands out as an essential tool for engineers and researchers. This device is designed to measure the strength and behavior of materials under tension. It can test various materials, from metals to plastics.

Many industries rely on this testing machine to ensure quality. For instance, in construction, verifying the strength of materials can prevent failures. However, not every lab invests in the right equipment. Sometimes, they settle for outdated machines. This can lead to inaccurate data and unforeseen risks.

Choosing a universal tensile testing machine can enhance testing procedures. It provides consistent results, ensuring materials meet required standards. Yet, some may wonder if the investment is worth it. Reflecting on your laboratory’s capabilities can guide this decision. The right machine can make all the difference in achieving precise outcomes.

Benefits of Using a Universal Tensile Testing Machine in Material Testing

A universal tensile testing machine is essential for material testing. It offers various benefits that enhance testing accuracy and efficiency. One of its primary advantages is versatility. It can test a wide range of materials, from metals to plastics. This flexibility saves laboratories time and resources. Different tests can be conducted without the need for multiple machines.

Precision is another critical benefit. Universal tensile testing machines provide consistent results, which are crucial for quality control. Operators can easily adjust parameters for specific tests, ensuring each sample is evaluated under the same conditions. However, it’s essential to calibrate the machine regularly. Failing to do so may lead to discrepancies in results.

Additionally, these machines often come with advanced software for data analysis. This feature simplifies interpreting results and compiling reports. Users can visualize data with graphs and charts. However, it's important to note that relying solely on software can sometimes mask potential issues. Human oversight is still necessary to catch anomalies. Overall, the universal tensile testing machine plays a vital role in ensuring high-quality material testing while providing areas for improvement in operation and analysis.

Key Features of Universal Tensile Testing Machines Explained

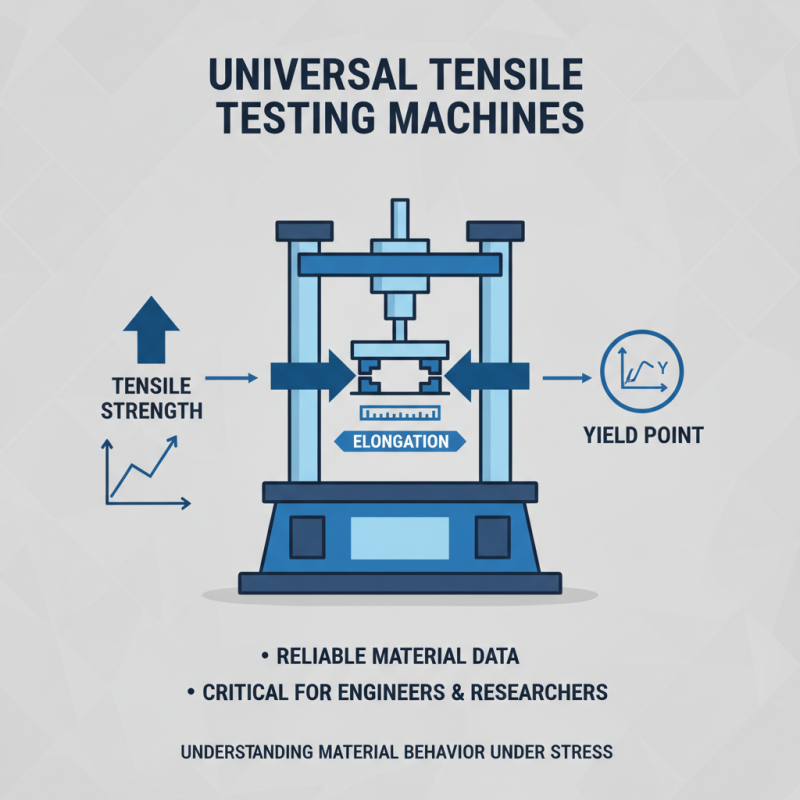

Universal tensile testing machines are central to material testing. They are versatile and can handle various materials, including metals, plastics, and textiles. The machines typically measure tensile strength, yield point, elongation, and more. According to a recent industry report, around 40% of tensile testing is conducted using these universal machines.

The key features of these machines include a broad testing range and high precision. They often come with advanced software for data analysis. These features allow for the collection of reliable data that can be used in research, manufacturing, or quality control. For instance, a study found that measurements taken with such machines can be accurate within 1% of actual values. This level of precision helps minimize errors in material assessments.

However, the choice of machine is not always straightforward. Users must consider factors like load capacity and accuracy. Some machines may fall short in specific testing scenarios. Therefore, it's crucial to evaluate testing needs carefully. The flexibility of these machines also requires operators to be trained adequately. Without proper training, results might be misleading, potentially causing costly mistakes in production.

Applications of Universal Tensile Testing Machines Across Industries

Universal tensile testing machines play a crucial role across various industries. They are essential for assessing materials' mechanical properties. This testing method helps ensure quality and compliance with industry standards.

In construction, tensile testing machines evaluate the strength of materials like steel and concrete. The American Society for Testing and Materials (ASTM) reported that over 40% of construction failures stem from subpar materials. Such machines are vital for preventing these issues. In the aerospace sector, manufacturers use them to test alloys and composites. These materials must meet strict safety regulations.

Automotive manufacturers rely on tensile testing for metal parts and polymers. A study indicated that nearly 30% of vehicle recalls are due to material failures. Regular testing can help reduce this risk significantly.

Tips: Always calibrate testing machines regularly to ensure accuracy. Also, consider the specific material requirements for your tests.

In the energy sector, tensile machines test resilience against extreme conditions. Reports indicate that materials for wind turbines are tested rigorously. This prevents costly failures during operations. However, not all tests are standardized. Understanding testing limits is essential for reliable results.

Applications of Universal Tensile Testing Machines Across Industries

The chart above illustrates the percentage usage of Universal Tensile Testing Machines in various industries, showcasing their importance in material testing across sectors such as construction, automotive, aerospace, electronics, and textiles.

Comparing Universal Tensile Testing Machines with Other Testing Methods

Universal tensile testing machines are essential in material testing. They provide reliable data on tensile strength, elongation, and yield point. This data is critical for engineers and researchers. It helps them understand how materials behave under stress.

When comparing universal tensile testing machines to other testing methods, some aspects stand out. Other methods, like compression or impact tests, often measure different properties. They might miss out on crucial tensile characteristics. This is where universal testers shine. They offer a broad range of testing capabilities in one machine. However, not all materials suit universal testing. Some softer materials might require specialized equipment.

It's important to reflect on testing accuracy. While universal tensile testing machines are versatile, human error can occur. Incorrect specimen preparation might lead to flawed results. Ensuring precision is vital for obtaining valuable data. Understanding these nuances can enhance material testing processes. It's essential to choose the right method for specific needs.

Best Practices for Operating a Universal Tensile Testing Machine

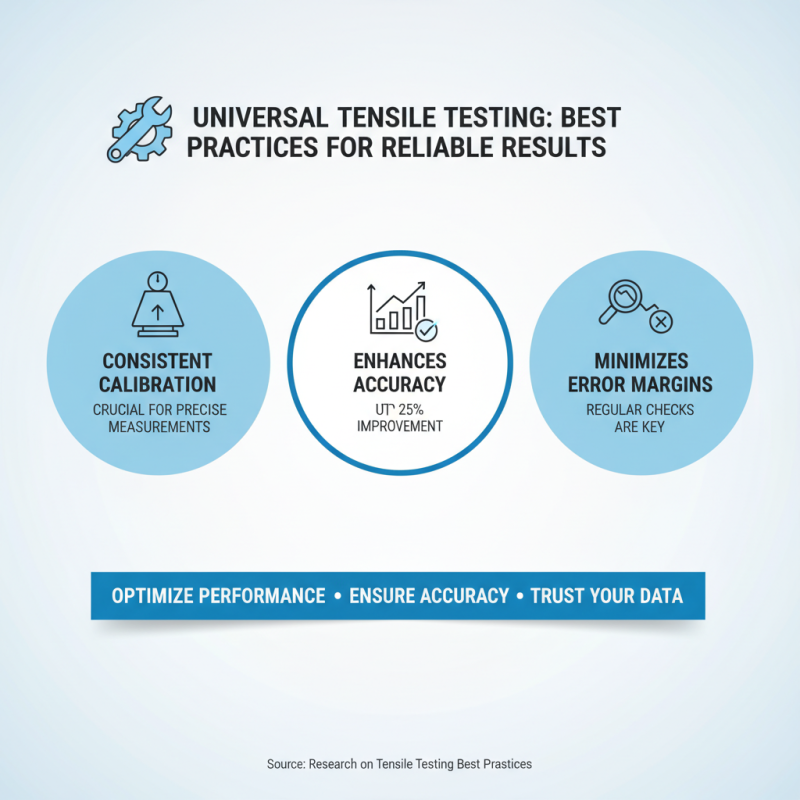

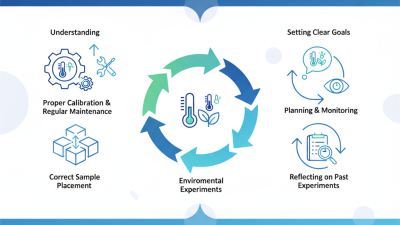

Operating a universal tensile testing machine requires adherence to best practices to ensure reliable results. Consistent calibration is crucial for precise measurements. Research shows that a well-calibrated machine can enhance accuracy by up to 25%. Regularly checking the calibration also minimizes error margins in tensile strength testing.

Attention to specimen preparation is equally important. Ensuring uniform dimensions and appropriate surface finishes can significantly affect test outcomes. Studies indicate that improper preparation can lead to a variance of 15% in tensile strength results. Operators should be trained to recognize and rectify any irregularities in specimens before testing.

Environmental factors should not be overlooked. Temperature and humidity can influence material behavior. For instance, testing environments that fluctuate more than 5 degrees Celsius can alter test results by 10% or more. Keeping a stable environment is essential. It’s a common issue for labs to underappreciate these factors, often leading to skewed data.

Related Posts

-

Understanding the Importance of Tensile Tester in Material Strength Analysis

-

Ultimate Guide to Tensile Testing Machines Benefits Features and Applications

-

2025 Top 10 Climatic Test Chambers for Accurate Environmental Testing

-

How to Use a Temperature and Humidity Chamber Effectively?

-

Why is a Test Chamber Essential for Quality Control in Product Development

-

How to Choose the Right Thermal Test Chamber for Your Needs?

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.