Top 10 Temperature Humidity Chamber Best Practices for Optimal Testing

In the field of material testing and product development, the significance of a temperature humidity chamber cannot be overstated. These controlled environments allow researchers and engineers to simulate varying temperature and humidity conditions that products may face in real-world scenarios. According to a recent report by the Material Testing Association, optimal testing conditions can improve product reliability by up to 30%, ultimately enhancing user satisfaction and reducing return rates.

Dr. Emily Thompson, a leading expert in environmental simulation, emphasizes the importance of best practices in utilizing temperature humidity chambers: "Consistent and precise testing protocols are essential to ensure that the data we collect reflects real-world performance." With her extensive experience in the field, Dr. Thompson highlights that adhering to best practices not only ensures accurate results but also provides a framework for innovation, allowing manufacturers to push the boundaries of product design.

As industries continue to evolve and consumer expectations heighten, understanding and implementing the top practices for using temperature humidity chambers has become crucial for achieving accurate and reliable testing results. This article will delve into the ten best practices that can help optimize the use of temperature humidity chambers, ensuring superior outcomes for product validation and development.

Importance of Temperature Humidity Chambers in Environmental Testing

Temperature humidity chambers play a crucial role in environmental testing, simulating a wide range of temperature and humidity conditions to assess the performance and reliability of products. These chambers are essential for industries such as pharmaceuticals, aerospace, and electronics, where products must withstand diverse environmental stresses. According to a report by the International Society of Automation, environmental testing can detect potential failures before products reach the market, reducing the risk of costly recalls and increasing customer satisfaction.

The importance of temperature humidity chambers is underscored by the growing demand for quality assurance in manufacturing processes. Research suggests that over 70% of product failures are linked to environmental factors, emphasizing the need for rigorous testing. Moreover, the National Institute of Standards and Technology has noted that proper testing conditions in controlled chambers can result in a 30% decrease in warranty claims for consumer electronics.

Implementing best practices within these chambers, such as regular calibration and precise monitoring of conditions, is vital in achieving accurate and reliable testing results, ultimately ensuring product longevity and functionality under real-world conditions.

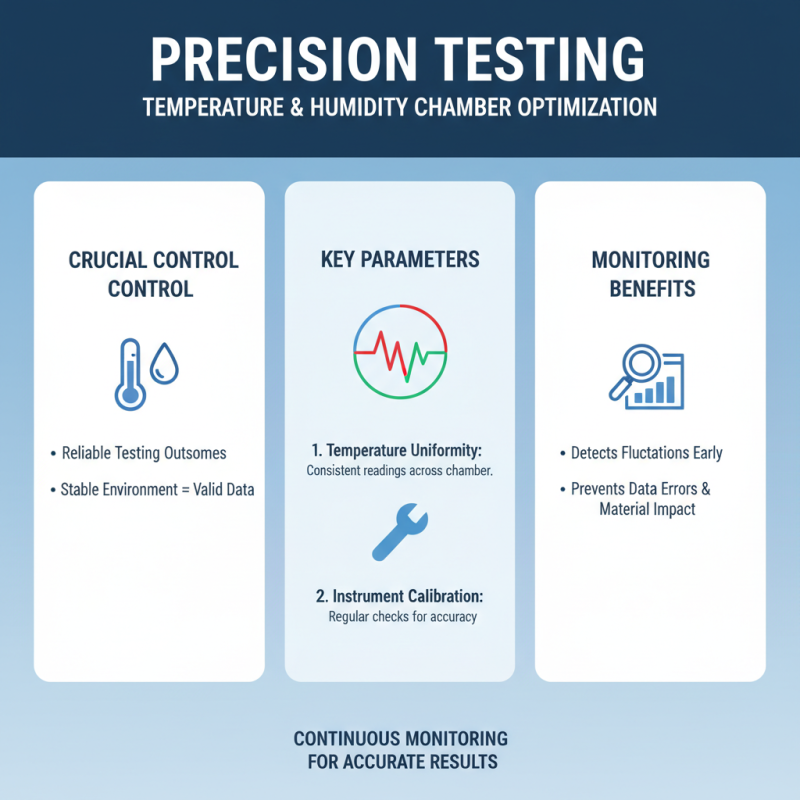

Key Parameters to Monitor for Effective Temperature and Humidity Control

Effective temperature and humidity control is crucial for reliable testing outcomes in temperature humidity chambers. One of the primary parameters to monitor is the consistency of temperature across the chamber. It's vital to regularly calibrate the instruments to ensure that the temperature reading accurately reflects the condition inside the chamber. Fluctuations in temperature can significantly impact the material or product being tested, leading to unreliable data. Continuous monitoring can help in detecting and rectifying issues before they affect the testing process.

Another key parameter is the relative humidity level, which should be maintained within set tolerance ranges. Too much or too little humidity can alter the properties of materials, especially in industries such as pharmaceuticals and electronics. Implementing a robust humidity control system, along with periodic checks, will help maintain the desired levels throughout the testing cycle. It’s also important to consider airflow within the chamber, as it can influence both temperature and humidity distribution, ensuring an even climate for accurate results.

Best Practices for Chamber Calibration and Maintenance

Calibration and maintenance of temperature humidity chambers are crucial for ensuring accurate and reliable testing results. According to a report by the American Society for Testing and Materials (ASTM), nearly 30% of testing failures can be attributed to inadequate calibration practices. Regular calibration ensures that the chamber operates within specified tolerances, significantly reducing potential errors. The industry standard recommends performing calibration at least once every six months, or more frequently for high-usage chambers. This not only guarantees precise temperature and humidity control but also prolongs the lifespan of the equipment.

Proper maintenance is equally essential, as it directly affects chamber performance and longevity. Statistics show that chambers that undergo regular maintenance see a reduction in operational downtime by up to 40%. Key maintenance practices include routine cleaning of sensors, checking for refrigerant leaks, and verifying that all mechanical components are functioning correctly. Implementing a scheduled maintenance plan based on the manufacturer's guidelines and industry recommendations can mitigate the risk of equipment failure and help maintain optimal testing conditions.

It is essential to train staff on these best practices, as knowledge and adherence to established protocols play a significant role in achieving consistent and accurate results in environmental testing.

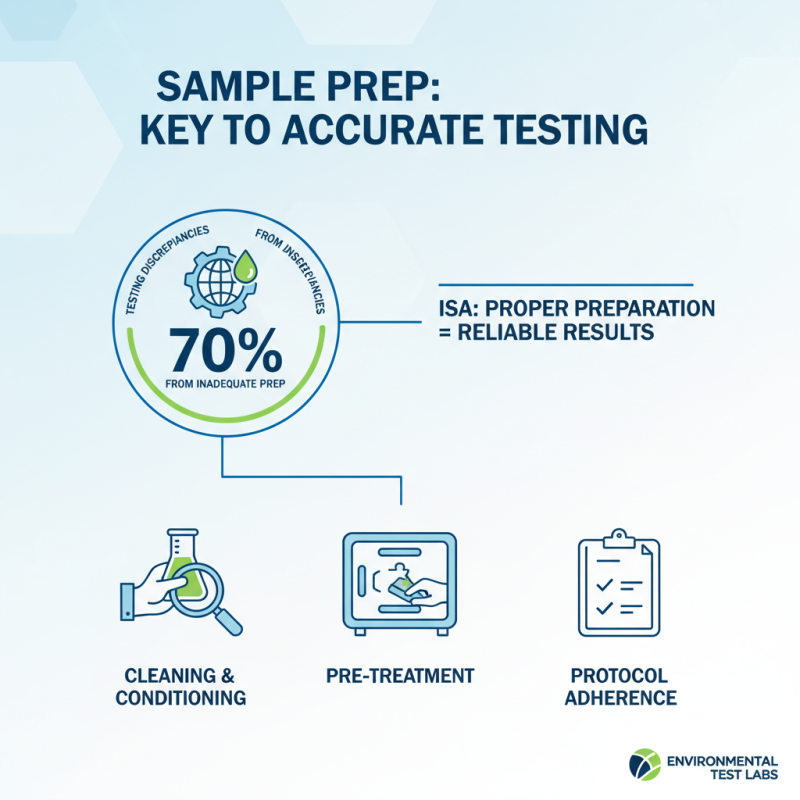

Strategies for Sample Preparation Before Testing

When preparing samples for testing in temperature and humidity chambers, proper sample preparation is crucial to ensure accurate and reliable results. According to the International Society of Automation (ISA), nearly 70% of testing discrepancies arise from inadequate sample preparation. This underscores the importance of taking the necessary steps before subjecting samples to controlled environmental conditions.

One critical strategy involves equilibrating samples to the testing environment. Studies indicate that acclimating samples to a specified temperature and humidity level before testing can reduce variability by up to 40%. This practice helps prevent thermal shock or moisture absorption, ensuring that the samples yield results that are a true reflection of their performance under specified conditions. Additionally, the American Society for Testing and Materials (ASTM) recommends conducting preliminary inspections and calibrations of samples to identify any inherent issues that could affect testing outcomes.

Moreover, meticulous labeling and documentation of samples prior to testing facilitates traceability and accuracy in results. A report by the National Institute of Standards and Technology (NIST) states that proper identification of samples contributes to a 25% reduction in testing errors. Implementing these strategies not only enhances the reliability of test results but also streamlines the testing process, ultimately leading to more efficient and effective product development cycles.

Common Pitfalls to Avoid in Temperature Humidity Testing Procedures

When conducting temperature humidity testing, avoiding common pitfalls is crucial for achieving reliable results. One major mistake is failing to properly prepare the chamber before testing begins. This includes ensuring that the chamber is clean and free from contaminants, as any residue can skew the results. Additionally, calibrating the equipment to ensure accurate readings is essential. Regular maintenance checks can help identify potential issues that may affect the performance of the chamber.

Another significant area where errors often occur is in the placement of samples within the chamber. Improper positioning can lead to uneven temperature and humidity distribution, ultimately resulting in misleading data. It's important to allow sufficient space around samples for air circulation and to avoid overcrowding the chamber. Moreover, continuously monitoring the conditions during the test is vital, as fluctuations can significantly impact the outcomes and invalidate the results if not addressed promptly. By adhering to these practices, testers can significantly improve the accuracy and credibility of their temperature humidity testing procedures.

Top 10 Temperature Humidity Chamber Best Practices for Optimal Testing - Common Pitfalls to Avoid in Temperature Humidity Testing Procedures

| Best Practice | Description | Common Pitfalls |

|---|---|---|

| Calibrate Equipment Regularly | Ensure accurate readings by calibrating instruments on a regular basis. | Neglecting calibration can lead to faulty results. |

| User Training | Train personnel in operating the temperature humidity chamber effectively. | Inexperienced users may incorrectly set parameters. |

| Environmental Control | Maintain stable external conditions for consistent internal chamber performance. | Fluctuating external conditions can skew results. |

| Regular Maintenance | Conduct preventive maintenance to ensure optimal operation. | Skipping maintenance can cause mechanical failures. |

| Adequate Space | Place the chamber in a suitable location with enough airflow. | Cramped spaces can affect temperature and humidity control. |

| Sample Placement | Position samples strategically for uniform exposure. | Improper placement can lead to inconsistent testing conditions. |

| Monitoring System | Utilize a robust monitoring system for real-time data. | Failure to monitor can result in unnoticed deviations. |

| Documentation | Keep detailed records of testing parameters and results. | Lack of documentation can hinder traceability. |

| Protocol Adherence | Follow established protocols strictly for reliability. | Deviating from protocols can render data invalid. |

Related Posts

-

Choosing the Right Temperature Humidity Chamber: A Comprehensive Comparison Guide

-

Top Climate Chamber Innovations for Research and Development in 2025

-

How to Choose the Right Force Tester for Your Manufacturing Needs

-

Exploring the Essential Role of Temperature and Humidity Chambers in Climate Simulation and Testing: A Deep Dive

-

How to Choose the Right Temperature Humidity Chamber for Your Specific Testing Needs

-

2025 Top 10 Climatic Test Chambers for Accurate Environmental Testing

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.