Why is a Test Chamber Essential for Quality Control in Product Development

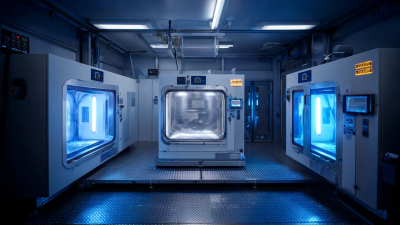

In the complex landscape of product development, the quality of a product is paramount to ensuring customer satisfaction and long-term success. One of the most critical aspects of maintaining high quality in production is the implementation of rigorous testing procedures. A vital component of these procedures is the "test chamber," which is designed to evaluate products under various environmental conditions. This controlled environment allows developers and engineers to simulate real-world usage scenarios, stress testing the product to ensure it meets predefined standards and performs reliably over its intended lifespan.

Test chambers play a crucial role in identifying potential weaknesses or failure points in a product, enabling teams to make informed decisions about design improvements and manufacturing processes. By subjecting products to extreme temperatures, humidity levels, and other challenging conditions, the test chamber provides insights that are essential for building durability and longevity into products. As industries increasingly prioritize quality control, integrating advanced testing methodologies, including the use of test chambers, becomes indispensable. Ultimately, the role of the test chamber extends beyond mere compliance; it embodies a commitment to excellence and continuous improvement in product development.

Importance of Quality Control in Product Development

Quality control plays an essential role in product development, impacting everything from customer satisfaction to compliance with industry standards. According to a report by the American Society for Quality, organizations with effective quality control systems can reduce defects by as much as 40%, leading to significant cost savings and increased consumer trust. This is particularly vital for industries such as automotive and aerospace, where safety and reliability are paramount.

Implementing systematic quality checks throughout the product development lifecycle ensures that any issues are caught early, before they translate into costly recalls or reputational damage.

Utilizing a test chamber as part of quality control allows developers to simulate real-world conditions, testing how products perform under various environmental factors. The data collected can guide necessary adjustments and innovations, ultimately refining the product before market release. A study published in the Journal of Product Innovation Management highlights that companies investing in robust quality control processes observe an average market share increase of 15%, underscoring the financial benefits of prioritizing product integrity.

Tips for enhancing quality control in product development include establishing clear criteria for success early in the process, integrating cross-functional teams to review product performance regularly, and investing in advanced testing technologies. Consistent monitoring and feedback loops help to ensure that every product meets or exceeds the evolving expectations of consumers and regulatory bodies, thus fostering long-term success.

Role of Test Chambers in Ensuring Product Reliability

Test chambers play a pivotal role in the product development lifecycle, especially when it comes to ensuring product reliability. These controlled environments simulate a wide range of conditions—from temperature fluctuations to humidity and vibration—allowing manufacturers to assess how their products will perform under various stresses. According to a report by the American Society for Testing and Materials (ASTM), more than 80% of companies that utilize environmental testing achieve significant improvements in product quality and longevity. This statistic underscores the necessity of incorporating test chambers into quality control protocols.

In addition to enhancing product reliability, test chambers are essential for regulatory compliance and customer satisfaction. Testing products under accelerated conditions helps identify potential failures before they reach the market, thereby reducing warranty claims and enhancing brand reputation. Data from the International Organization for Standardization (ISO) suggests that products that undergo rigorous testing and validation processes are 50% less likely to encounter performance issues in the field. As customers become increasingly discerning, the importance of utilizing test chambers cannot be overstated; they ensure that products not only meet but exceed market expectations in terms of reliability and durability.

Types of Tests Conducted in a Test Chamber

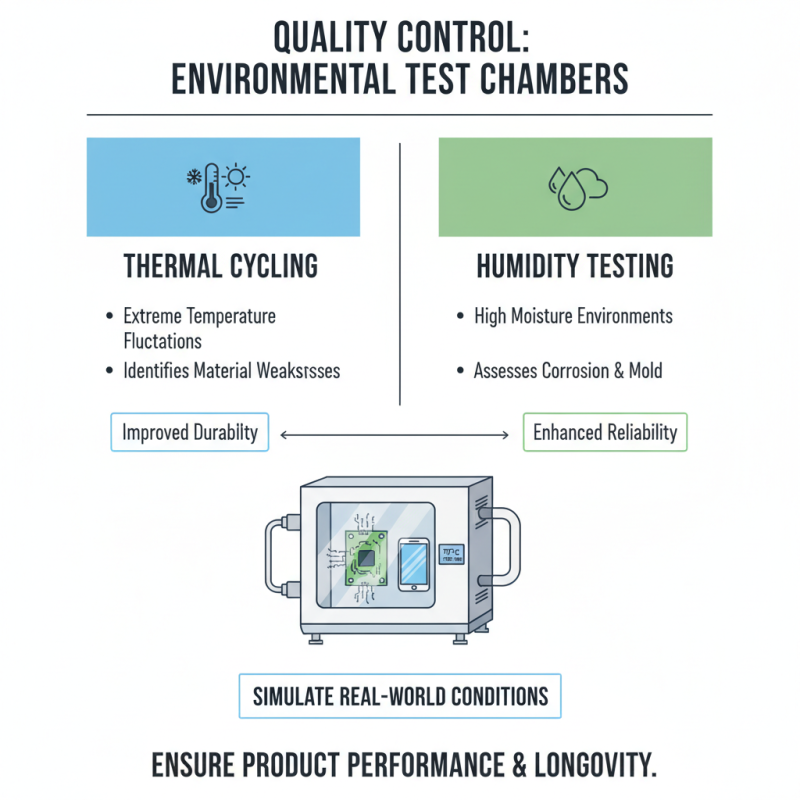

Test chambers play a pivotal role in quality control by simulating various environmental conditions to ensure that products can withstand real-world scenarios. One common type of test conducted in these chambers is thermal cycling, where products are subjected to extreme temperature fluctuations. This test helps identify potential weaknesses in materials and components, allowing engineers to improve durability and reliability. Another crucial test carried out in a test chamber is humidity testing, which evaluates how well a product can perform in high humidity environments. By controlling moisture levels, manufacturers can assess the likelihood of corrosion, mold growth, or material degradation over time.

Additionally, vibration testing is frequently performed in test chambers, especially for products intended for transportation and field use. This process simulates the physical stresses that items might experience during shipping or operation, ensuring that they can maintain their functionality and integrity under dynamic conditions. Combining these various testing methods within a controlled test chamber helps developers pinpoint issues early in the product lifecycle, ultimately leading to improved product quality and customer satisfaction.

Benefits of Using Test Chambers for Quality Assurance

Test chambers have become indispensable tools in product development, significantly enhancing quality assurance processes across various industries. Utilizing controlled environments, test chambers allow for rigorous testing of products under specific conditions such as temperature, humidity, and pressure. According to a recent report from the International Organization for Standardization (ISO), approximately 80% of manufacturers using test chambers noted a reduction in product failures and recalls, showcasing their pivotal role in ensuring product reliability.

The primary benefit of employing test chambers is their ability to simulate real-world conditions that products may encounter during their lifecycle. This simulation helps in identifying potential weaknesses and areas for improvement early in the development process. For instance, a study published in the Journal of Quality Assurance highlighted that products tested in simulated extreme conditions experienced a 60% decrease in performance issues after reaching the market compared to those that underwent less rigorous testing.

**Tips:** When setting up a test chamber, ensure proper calibration of monitoring equipment to maintain accuracy in test results. Additionally, consider conducting regular maintenance checks on the chamber to avoid unexpected discrepancies in controlled environments. Establishing clear protocols for testing can also maximize the efficiency and effectiveness of your quality assurance processes.

Case Studies: Successful Implementation of Test Chambers in Industries

In many industries, the integration of test chambers into product development processes has proven to be a pivotal factor in ensuring quality control. For instance, a notable study by the American Society for Quality (ASQ) highlighted that organizations utilizing environmental testing showed a 32% reduction in product failures, demonstrating the significant impact of test chambers on product reliability. These controlled environments enable precise simulations of various conditions, allowing companies to assess how products will perform under stress, temperature fluctuations, and moisture exposure before they hit the market.

The automotive sector provides a compelling example of successful test chamber implementation. According to a report from the Society of Automotive Engineers (SAE), manufacturers who adopted chamber testing methodologies reported a 40% decrease in warranty claims over three years. By simulating extreme weather conditions and mechanical stressors, developers can innovate designs that adequately address potential field failures, thereby streamlining the overall production process and enhancing consumer trust in product durability. Overall, the strategic use of test chambers not only uplifts quality control measures but also catalyzes product innovation across various industries.

Related Posts

-

Essential Checklist for Selecting the Right Temperature Test Chamber for Your Testing Needs

-

Choosing the Right Temperature Humidity Chamber: A Comprehensive Comparison Guide

-

Exploring the Role of Climatic Test Chambers at the 138th Canton Fair 2025 in China's Testing Industry

-

2025 Top 10 Climatic Test Chambers for Accurate Environmental Testing

-

Top Climate Chamber Innovations for Research and Development in 2025

-

The Ultimate Guide to Choosing the Right Environmental Test Chamber for Your Laboratory Needs

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.