Ultimate Guide to Tensile Testing Machines Benefits Features and Applications

Tensile testing machines have become indispensable tools in material science, engineering, and manufacturing sectors. These machines play a crucial role in determining the mechanical properties of materials, providing vital data on tensile strength, yield strength, and elongation. According to a recent report by Smith & Associates, the global tensile testing machine market is projected to reach $500 million by 2025, driven by increasing demand for quality control and assurance across various industries such as aerospace, automotive, and construction.

Dr. Jane Anderson, a noted expert in material testing technology, remarked, “The accuracy and reliability of a tensile testing machine are paramount in ensuring that materials meet their required specifications and safety standards.” Her insight highlights the importance of these machines in maintaining the integrity of products, as consistent testing results can lead to improved design and manufacturing processes. As industries continue to evolve, the integral role of tensile testing machines will only increase, further emphasizing their significance in achieving innovation and safety in material applications.

Overview of Tensile Testing Machines and Their Purpose

Tensile testing machines play a crucial role in evaluating the mechanical properties of materials, making them indispensable in various industries such as manufacturing, construction, and materials science. These machines are designed to apply controlled tension to a sample until it fails, allowing engineers and researchers to measure essential parameters such as tensile strength, yield strength, and elongation. According to a report from MarketsandMarkets, the tensile testing market is projected to grow significantly, driven by increasing demand for quality assurance and regulatory compliance across various sectors.

The primary purpose of tensile testing machines is to help identify how materials will behave under different forces and conditions. This information is vital for ensuring the safety and durability of products, from aerospace components to everyday consumer goods. Advanced machines today are equipped with features such as digital interfaces, automated load control, and data analysis software, enhancing precision and user experience. Industry reports highlight that integrating these features can improve test accuracy by up to 25%, showcasing advancements in technology that streamline material testing processes.

Tip: When selecting a tensile testing machine, consider the maximum load capacity and the range of materials you will be testing to ensure optimal performance and versatility. Moreover, regular maintenance can significantly enhance the lifespan and accuracy of your equipment, allowing for consistent and reliable testing results.

Ultimate Guide to Tensile Testing Machines: Benefits, Features, and Applications

This chart illustrates the various strength measurements obtained from tensile testing machines, highlighting the critical parameters such as compressive strength, tensile strength, yield strength, elongation, and reduction of area.

Key Benefits of Using Tensile Testing Machines in Industry

Tensile testing machines play a crucial role in various industries by providing vital data on material properties, which in turn enhances product quality and safety. One of the primary benefits is their ability to measure tensile strength, elongation, and yield point characteristics of materials. According to a report by the Materials Research Society, materials exhibiting high tensile strength can help manufacturers achieve better performance and durability in their products, reducing the risk of failures in critical applications such as aerospace and automotive sectors.

Another significant advantage of using tensile testing machines is their contribution to quality control and assurance processes. Industries that employ stringent quality guidelines can leverage the data obtained from tensile tests to comply with international standards, thus ensuring consistent product performance. A survey by the American Society for Testing and Materials highlighted that manufacturers utilizing advanced tensile testing are 30% more likely to meet or exceed compliance standards. This not only reduces material waste but also minimizes the need for costly recalls, ultimately leading to greater efficiency and customer satisfaction. Through ongoing material analysis, industries can innovate and enhance their offerings based on real-time performance data.

Ultimate Guide to Tensile Testing Machines Benefits Features and Applications

| Feature/Benefit | Description | Application Areas |

|---|---|---|

| Accuracy | Provides highly precise measurements of material properties. | Metal, Plastic, Textile industries |

| Versatility | Can test a wide range of materials including composites and elastomers. | Research, Development and Quality Control |

| User-friendly Interface | Modern tensile testers come with intuitive software for easy operation. | Laboratories, Educational Institutions |

| Real-time Data Analysis | Allows for immediate feedback and data recording during tests. | Manufacturing, Aerospace |

| Material Characterization | Helps in understanding the mechanical properties of materials. | Construction, Automotive |

Essential Features to Look for in Tensile Testing Machines

When considering the purchase of a tensile testing machine, it is essential to focus on key features that can significantly impact the accuracy and efficiency of materials testing. One fundamental feature is the load capacity of the machine. For instance, according to a report by ResearchAndMarkets, the global tensile testing machine market is projected to grow by over 5% annually, reflecting the increasing demand for high-capacity machines that can test a wide range of materials, from metals to polymers. A machine with adjustable load capacity ensures versatility and can accommodate both small and large samples, making it suitable for diverse applications.

Another critical feature to evaluate is the data acquisition system. A high-quality tensile testing machine should provide real-time data logging, allowing for detailed analysis of material behavior under stress. Advanced systems can offer digital displays, enabling users to visualize results instantly and make informed decisions quickly. As highlighted in an industry review by ASTM International, precise data collection is crucial for R&D, as it aids in material certification and quality control processes. Additionally, programming capabilities for custom test parameters can enhance testing efficiency, ensuring that clients receive reliable and relevant data tailored to their specific needs.

Common Applications of Tensile Testing in Various Industries

Tensile testing is a crucial process utilized across various industries to assess the mechanical properties of materials. In construction, for instance, steel and concrete are frequently subjected to tensile tests to ensure their strength and durability.

A report by the American Concrete Institute highlights that tensile testing can determine the optimal load capacities of structural materials, thus contributing to safer building practices. Engineers use the data derived from these tests not only for design validations but also for compliance with safety regulations.

In the automotive industry, tensile testing is essential for evaluating the performance of metals and polymers used in vehicle manufacturing. According to the Society of Automotive Engineers, nearly 70% of material failures occur due to tensile strength inadequacies, making the proper evaluation of materials vital for vehicle safety. Through tensile tests, manufacturers can identify weaknesses in materials before assembling them into critical components, leading to enhanced performance and risk mitigation.

This practice is not only about meeting industry standards but also about pushing innovation, as companies turn to advanced materials that promise better results under stress.

Meanwhile, the aerospace sector relies heavily on tensile testing to ensure the safety and integrity of aircraft components. The Federal Aviation Administration mandates rigorous material testing; any compromise in tensile strength can lead to catastrophic failures. Industry reports indicate that materials used in the aerospace industry must withstand high tensile loads, particularly at extreme altitudes and temperatures, making the insights gained from tensile testing invaluable for manufacturers seeking to innovate while adhering to stringent safety standards.

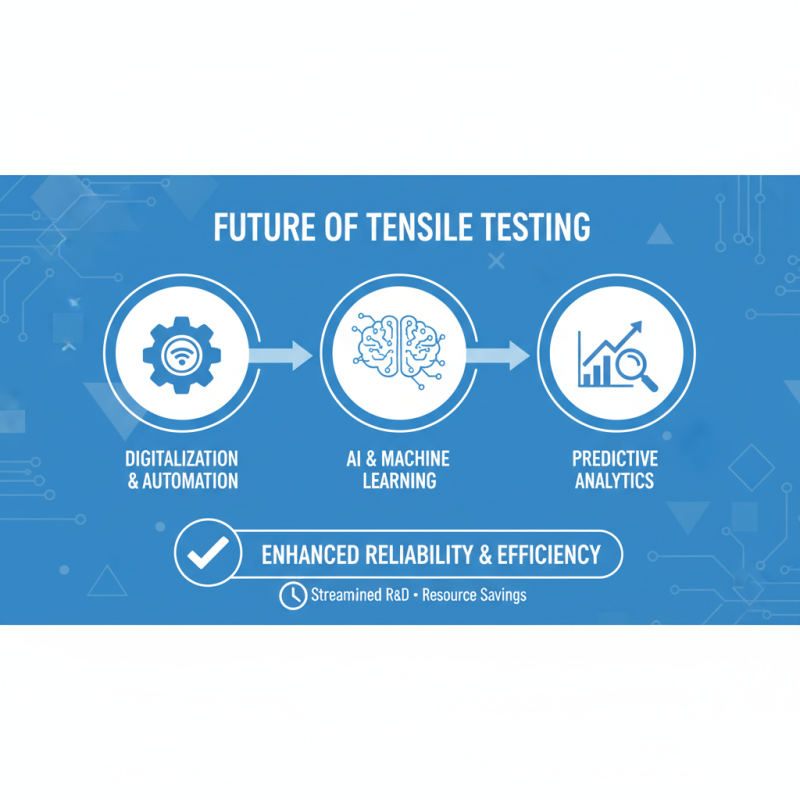

Future Trends in Tensile Testing Technology and Innovations

The landscape of tensile testing technology is evolving rapidly, driven by advancements in digitalization and automation. Future trends suggest a significant shift towards integrating AI and machine learning, enabling more accurate data analysis and interpretation. With the ability to predict material behaviors under various conditions, these innovations promise to enhance the reliability of tensile testing, making it an indispensable tool for material scientists and engineers. This predictive capability not only streamlines the testing process but also saves time and resources, ultimately leading to more efficient research and development cycles.

Additionally, the incorporation of advanced materials and sensors into tensile testing machines is set to revolutionize the industry. For instance, nanotechnology-enabled sensors can provide real-time monitoring of stress and strain, enhancing the precision of measurements. As manufacturers prioritize sustainability, eco-friendly materials and energy-efficient designs will likely become standard in tensile testing machines. This trend not only reflects a commitment to environmental responsibility but also meets the increasing demand for greener manufacturing practices, showcasing how innovation can align with sustainability goals in testing technologies. As we look toward the future, the convergence of these advancements will undoubtedly reshape the capabilities and applications of tensile testing machinery across various sectors.

Related Posts

-

Essential Guide to Understanding Universal Tensile Testing Machines for Accurate Material Analysis

-

Understanding the Importance of Tensile Tester in Material Strength Analysis

-

Why Investing in a Tensile Tester Can Transform Your Quality Control Process

-

Unlocking the Secrets: How a Gloss Meter for Paint Transforms Surface Finishing

-

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

-

Essential Checklist for Selecting the Right Temperature Test Chamber for Your Testing Needs

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.