Exploring the Essential Role of Temperature and Humidity Chambers in Climate Simulation and Testing: A Deep Dive

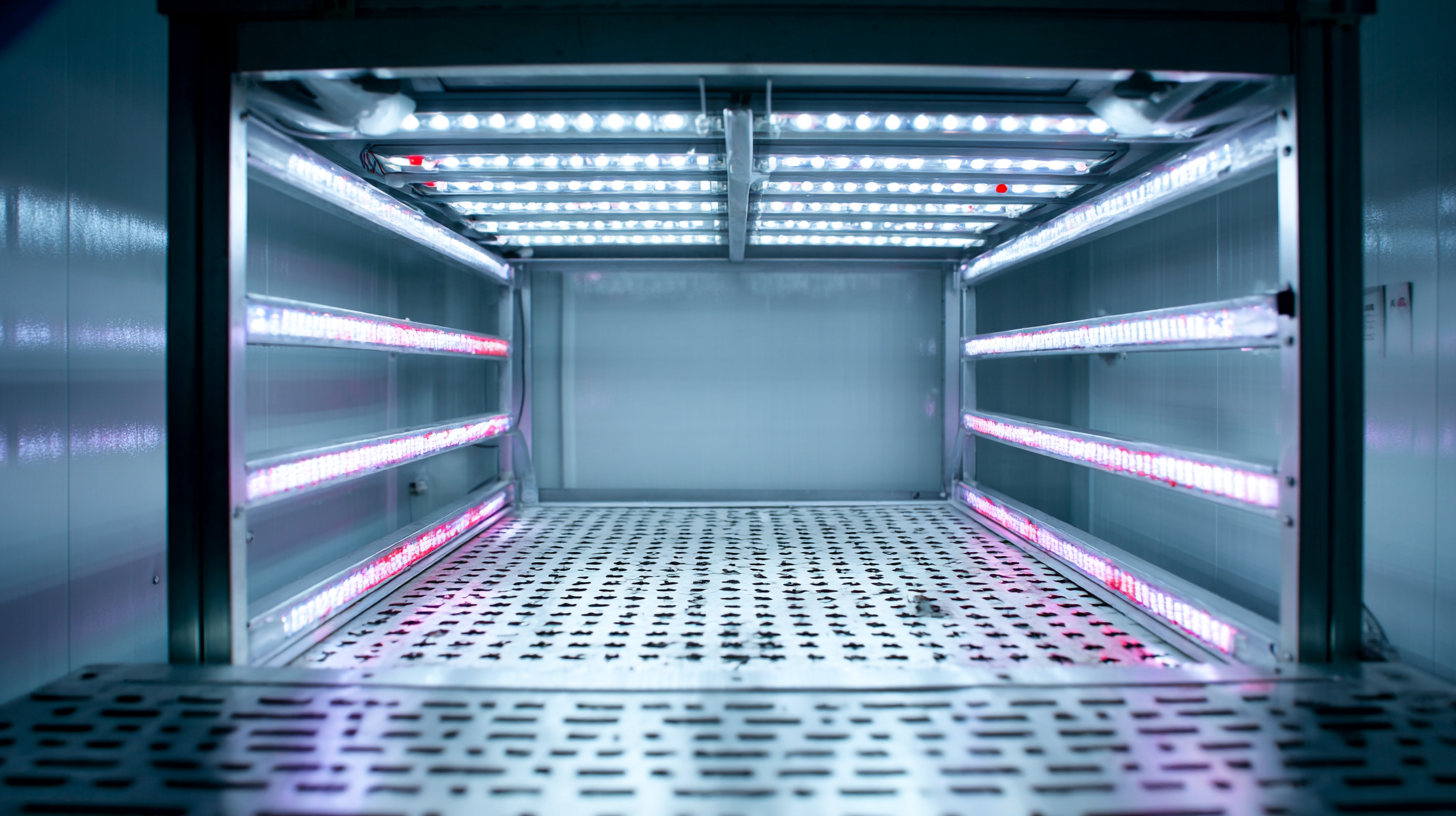

In today's rapidly evolving technological landscape, the importance of climate simulation and testing cannot be overstated, particularly in fields such as pharmaceuticals, automotive, and electronics. A temperature and humidity chamber plays a vital role in this process by providing precise environmental conditions that allow for rigorous testing and validation of products under various climate scenarios. According to a recent market report by Research and Markets, the global environmental chamber market is projected to reach $1.17 billion by 2027, driven by the increasing demand for advanced testing capabilities across industries. These chambers not only help in assessing the reliability and durability of products but also ensure compliance with industry standards. As climate change continues to impact product performance, the need for robust and accurate simulation tools, such as temperature and humidity chambers, becomes increasingly critical for manufacturers striving to innovate and maintain competitive advantage.

The Importance of Temperature and Humidity Chambers in Environmental Testing

Temperature and humidity chambers play a crucial role in environmental testing across various industries, enabling researchers to simulate real-world conditions accurately. According to a report from MarketsandMarkets, the environmental testing market is projected to reach $12.76 billion by 2025, driven significantly by the need for stringent quality assurance protocols in industries like pharmaceuticals and electronics. These chambers provide a controlled environment to evaluate how products perform under varying temperature and humidity levels, ensuring they meet regulatory standards and consumer expectations.

One of the key advantages of using temperature and humidity chambers is their ability to replicate extreme environmental conditions. For instance, the International Organization for Standardization (ISO) indicates that many products, from medical devices to automotive components, undergo testing at temperatures ranging from -70°C to +150°C. Additionally, maintaining specific humidity levels is equally vital; the American Society for Testing and Materials (ASTM) suggests that fluctuations in humidity can affect the physical and chemical properties of materials, leading to failures if not properly tested. As industries continue to prioritize environmental sustainability and product reliability, the significance of these chambers in testing protocols will only grow.

Key Applications of Climate Simulation in Research and Industry

Temperature and humidity chambers play a crucial role in climate simulation, serving various sectors including research and industry. These controlled environments allow scientists to replicate different climatic conditions, enabling the testing of materials, products, and processes under specific temperature and humidity settings. For instance, in the automotive industry, manufacturers use these chambers to assess how vehicle components withstand extreme weather conditions. Similarly, in pharmaceuticals, it’s essential to ensure that drugs maintain efficacy under varying storage conditions, which can be accurately tested in such chambers.

Tips for effective use of temperature and humidity chambers include regularly calibrating the equipment to maintain precision and conducting preliminary tests to determine the optimal parameters for your specific application. Understanding the material properties you're testing can also inform how you set up your simulations. Additionally, be mindful of condensation issues within the chamber, as moisture can impact sensitive tests, particularly in electronic component assessments.

In the field of agriculture, climate simulation is vital for research on crop resilience. By simulating potential future climate scenarios, researchers can evaluate how different plant varieties may perform under projected temperature and humidity shifts. This data is not only essential for breeding programs but also for developing strategic agricultural practices that enhance food security in a changing climate.

Impact of Temperature and Humidity on Climate Simulation

This bar chart illustrates the two key parameters - Temperature and Humidity - as essential factors in climate simulation processes. These parameters are crucial for various research and industrial applications, where controlled environments are necessary for testing and development.

Design Principles for Effective Temperature and Humidity Chambers

Temperature and humidity chambers are indispensable in simulating and testing environmental conditions for a wide range of applications, from electronics to pharmaceuticals. Designing effective chambers requires a thorough understanding of the principles that dictate temperature and humidity control. For instance, a study from the International Society for Pharmaceutical Engineering highlights that maintaining precise humidity levels is crucial for preserving the integrity of active pharmaceutical ingredients during testing. A chamber's ability to replicate variations in temperature and humidity with an accuracy of ±0.5°C and ±2% RH is often essential for ensuring reliable results.

When creating a temperature and humidity chamber, several key design principles should be prioritized. Firstly, insulation materials play a vital role in minimizing external influences on the internal environment. Moreover, integrating advanced control systems not only enhances energy efficiency but also ensures rapid recovery after door openings. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers, optimizing airflow within the chamber can significantly enhance uniformity and reduce hot spots, ensuring consistent testing conditions.

**Tip:** Regular calibration of sensors is essential to maintain accuracy within the chamber. It’s recommended to perform these calibrations at least once every six months to avoid discrepancies that could affect testing outcomes.

**Tip:** Consider implementing data logging systems that automatically record temperature and humidity changes over time. This feature allows easier compliance with regulatory requirements and aids in analyzing trends and anomalies in environmental conditions during tests.

Challenges and Solutions in Climate Testing Environments

Climate testing environments, specifically temperature and humidity chambers, play a critical role in assessing the performance and durability of materials and products under simulated environmental conditions. However, creating and maintaining these conditions present several challenges. For instance, achieving precise temperature ranges—often between -40°C to +100°C—combined with humidity levels of 10% to 98% can strain even the most advanced equipment. According to a 2021 report by the International Society for Testing and Evaluation, nearly 30% of climate simulation setups report issues with maintaining stable environmental conditions, which can severely impact testing accuracy.

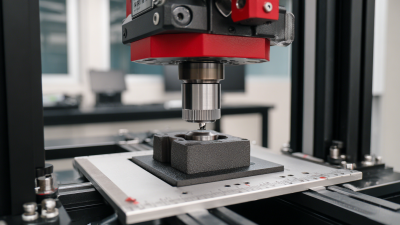

One of the primary solutions to these challenges lies in the integration of advanced monitoring technologies. Real-time data collection and analysis can enhance chamber performance and ensure consistency in tests. A study by the American Society for Testing and Materials (ASTM) highlights that implementing automated control systems can reduce deviations in temperature and humidity by up to 25%. Moreover, the development of energy-efficient chambers not only balances operational costs but also meets the increasing demand for sustainable practices in testing environments. As the industry adapts to these challenges, innovative approaches will pave the way for more reliable and efficient climate testing.

Future Trends in Climate Simulation Technology and Its Applications

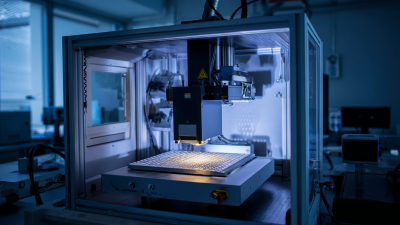

As climate simulation technology advances, the integration of sophisticated temperature and humidity chambers plays a pivotal role in research and industrial applications. These chambers not only replicate extreme environmental conditions but also allow for the testing of materials, products, and ecosystems under controlled settings. Future trends indicate a shift toward more automated, user-friendly systems that leverage artificial intelligence to enhance precision and efficiency in climate testing.

Tips for ensuring effective use of temperature and humidity chambers include regular calibration to maintain accuracy and using real-time monitoring systems to track changes within the chamber environment. Additionally, incorporating data analytics can help interpret results more effectively, guiding research and development in a faster, more informed manner.

As industries increasingly acknowledge the importance of climate resilience, the demand for advanced simulation technologies rises. Innovations such as modular chamber designs and remote operation capabilities are expected to empower researchers and manufacturers alike, enabling them to conduct complex experiments with greater ease and speed, ultimately driving more sustainable practices across various sectors.

Exploring the Essential Role of Temperature and Humidity Chambers in Climate Simulation and Testing: A Deep Dive

| Dimension | Description | Current Trends | Future Applications |

|---|---|---|---|

| Temperature Control | Regulating temperature for precise simulations | Smart thermoregulation technologies | Integration in renewable energy testing |

| Humidity Control | Maintaining optimal humidity levels | Advanced moisture detection systems | Material resilience testing in varied climates |

| Data Logging | Recording environmental conditions during tests | IoT-enabled data capture and analysis | Predictive analytics in climate research |

| Simulation Accuracy | Ensuring realistic simulation conditions | Enhanced calibration techniques | Climate change impact modeling |

Related Posts

-

Solutions for Tailored Environmental Test Chamber Applications

-

How to Choose the Right Temperature Humidity Chamber for Your Specific Testing Needs

-

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

-

Why Investing in a Tensile Tester Can Transform Your Quality Control Process

-

Ultimate Guide to Understanding Thermal Chambers: Selection, Usage, and Best Practices

-

Exploring the Role of Climatic Test Chambers at the 138th Canton Fair 2025 in China's Testing Industry

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.