Understanding the Importance of Tensile Tester in Material Strength Analysis

In today's materials science and engineering landscape, the significance of a tensile tester cannot be overstated. As industries strive for improved product performance and reliability, understanding material strength becomes paramount. According to a report by Research and Markets, the global tensile testing machine market is projected to reach USD 1.4 billion by 2026, driven by the rising demand for quality assurance in various sectors including automotive, aerospace, and construction.

Tensile testers play a crucial role in assessing the mechanical properties of materials, providing vital data on tensile strength, elongation, and yield point. This information not only facilitates compliance with industry standards but also aids in the development of innovative materials designed to meet the increasing performance demands. Thus, mastering the utilization of tensile testers is essential for engineers and materials scientists dedicated to enhancing safety and durability in product design and manufacturing processes.

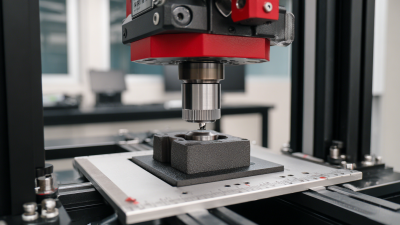

The Role of Tensile Testers in Evaluating Material Durability

Tensile testers play a crucial role in evaluating material durability, offering precise measurements that reveal how materials behave under stress. By applying a controlled tensile load to a sample, these testers provide insights into the material's strength, elasticity, and overall toughness. This process is essential in industries where material performance is critical, such as construction, aerospace, and manufacturing. Understanding how a material responds to tensile forces helps engineers to select appropriate materials for specific applications, ensuring reliability and safety.

Moreover, the data obtained from tensile testing allows manufacturers to refine their material formulations and processing methods. By identifying weaknesses or failure points in a material, companies can implement improvements that enhance durability. This iterative process not only fosters innovation in material science but also contributes to more sustainable practices by reducing waste and increasing the longevity of products. Ultimately, the integration of tensile testing into the material development process is vital for optimizing performance and ensuring the integrity of structures and products used in everyday life.

Understanding the Importance of Tensile Tester in Material Strength Analysis

| Material Type | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|

| Steel | 400-600 | 250-350 | 15-25 | 210 |

| Aluminum Alloy | 290-550 | 150-300 | 10-20 | 70 |

| Polycarbonate | 60-80 | 60-70 | 100-200 | 2.4 |

| Titanium Alloy | 900-1,000 | 800 | 10-15 | 110 |

| Copper | 200-300 | 70-210 | 30-40 | 110 |

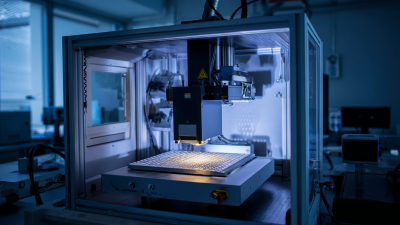

Key Features of an Advanced Tensile Testing Machine

An advanced tensile testing machine is crucial for comprehensively analyzing material strength, ensuring quality and performance in manufacturing processes. Key features that define these machines include a high precision load cell, an extensometer for accurate elongation measurement, and robust software capabilities for data analysis. According to a report by the Materials Testing Institute (MTI), the accuracy of tensile testing can improve material selection processes by up to 30%, underscoring the importance of precise measurement in material strength analysis.

Another critical feature is the ability to conduct tests at varying temperatures and humidity levels, which can directly affect the results. Advanced tensile testers often include environmental chambers that allow for standardized testing conditions. The ASTM E8/E8M standard, widely quoted in industry literature, suggests that all tensile tests should adhere to specified conditions to ensure reliability and reproducibility of results. This makes tensile testing machines integral to industries ranging from aerospace to automotive.

Tips: When selecting a tensile testing machine, ensure that it meets international standards for accuracy and reliability. Additionally, investing in comprehensive software that provides detailed analytics can significantly streamline your quality control processes. Always keep your equipment calibrated to maintain data integrity during testing.

Five Common Materials Assessed Using Tensile Testing

Tensile testing is a crucial process in evaluating the mechanical properties of various materials. Among the most commonly assessed materials are metals, plastics, textiles, and composites. Each of these materials exhibits unique characteristics that can be effectively analyzed through tensile testing, providing essential data for engineers and manufacturers.

Metals, such as stainless steel and aluminum, are often subjected to tensile tests to determine their strength, ductility, and elasticity. This information is vital for applications that demand precise load-bearing capabilities. Similarly, plastics are frequently analyzed to understand their tensile strength, elongation, and overall performance under stress.

Textiles, which require specific tensile characteristics for applications in fashion and industrial use, are also evaluated using this method. Lastly, composite materials, which combine different components to enhance performance, are assessed through tensile testing to uncover their unique structural benefits and weaknesses, ensuring they meet industry standards.

Understanding the Relationship Between Tensile Strength and Material Applications

Tensile strength is a critical parameter in material science, directly influencing how materials are used in various applications across numerous industries. As reported by the American Society for Testing and Materials (ASTM), tensile strength refers to the maximum amount of tensile (stretching) stress that a material can withstand before failure. For instance, metals such as steel exhibit a tensile strength ranging from 370 to 700 megapascals (MPa), making them suitable for structural applications where strength is paramount. In contrast, polymers generally possess lower tensile strengths, often around 35 to 60 MPa, making them ideal for applications requiring flexibility and lightweight characteristics, such as in automotive interiors or consumer goods.

Furthermore, the relationship between tensile strength and material applications is increasingly emphasized by manufacturers seeking to optimize performance and safety. According to a study by the Materials Research Society, materials with high tensile strength are essential in critical applications like aerospace and civil engineering, where structural integrity is non-negotiable. For instance, composite materials that incorporate carbon fibers can achieve tensile strengths exceeding 1,500 MPa, thus permitting their use in aerospace components that must endure extreme conditions while minimizing weight. This clear correlation between tensile strength and application suitability underscores the need for precise tensile testing as an essential step in the material selection process for engineers and designers.

Understanding Tensile Strength in Various Materials

This bar chart illustrates the tensile strength of different materials commonly used in engineering. Tensile strength is a critical property that influences the choice of material for various applications.

Choosing the Right Tensile Tester: A Comprehensive Guide

When it comes to material strength analysis, selecting the appropriate tensile tester is crucial. The right instrument ensures accurate measurements and reliable data, which are essential for understanding the mechanical properties of materials. Factors to consider include the tensile test method, the capacity of the tester, and the specific material characteristics. For example, materials like metals and plastics require different testing approaches, so understanding these variations can guide users in making informed decisions.

Another important aspect to consider is the additional features of tensile testers, such as software integration and data analysis capabilities. Modern tensile testers often come equipped with advanced technology that facilitates real-time monitoring and reporting of test results. Assessing the ease of use, maintenance requirements, and manufacturer support can further influence the choice. By carefully evaluating these elements, engineers and material scientists can select a tensile tester that not only meets their current testing needs but also accommodates future requirements in material development and quality assurance.

Related Posts

-

Why Investing in a Tensile Tester Can Transform Your Quality Control Process

-

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

-

7 Compelling Reasons to Invest in Thermal Chambers for Your Business Success

-

How to Choose the Right Color Spectrophotometer for Your Needs

-

Essential Checklist for Selecting the Right Temperature Test Chamber for Your Testing Needs

-

How to Choose the Right Force Tester for Your Manufacturing Needs

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.