What is an Environmental Test Chamber and How Does It Work?

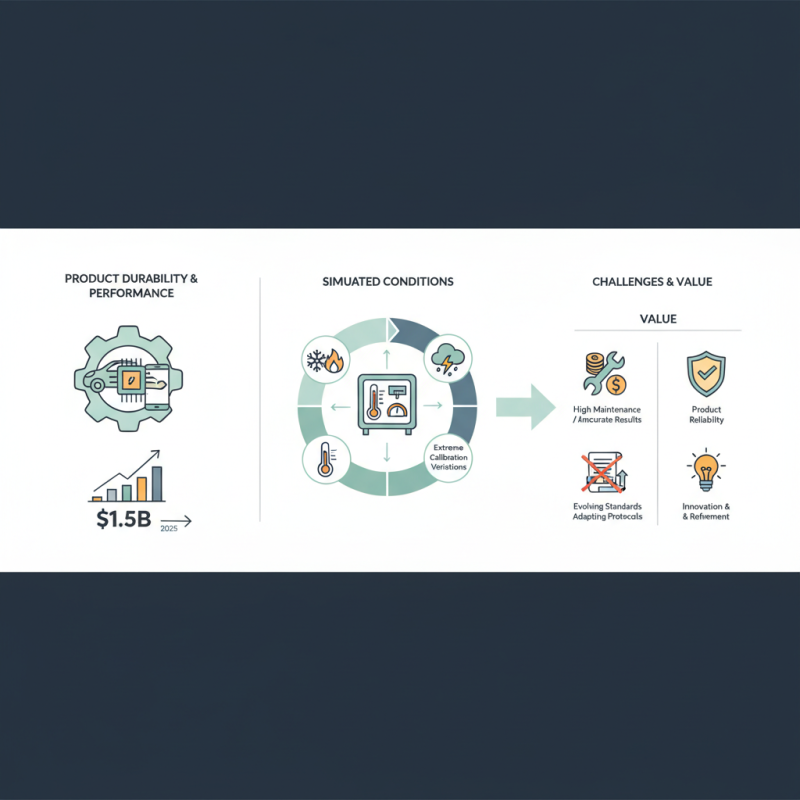

An environmental test chamber is essential for assessing product durability and performance. Industries like aerospace, automotive, and electronics rely heavily on these chambers. According to a recent market report, the global environmental test chamber market is expected to grow significantly, reaching $1.5 billion by 2025. These facilities simulate extreme conditions, including temperature, humidity, and pressure variations.

However, operating an environmental test chamber is not without challenges. Maintenance costs can be high, and improper calibration may lead to inaccurate test results. For instance, a flawed test could lead a manufacturer to overlook critical product failures. Moreover, with evolving standards, companies must frequently adapt their testing protocols. This can create further strain on resources.

Despite these obstacles, the value of an environmental test chamber cannot be overstated. It plays a pivotal role in ensuring product reliability and compliance with industry standards. Organizations must continuously refine their testing processes. Embracing innovation while addressing setbacks can enhance the effectiveness of environmental testing.

What is an Environmental Test Chamber?

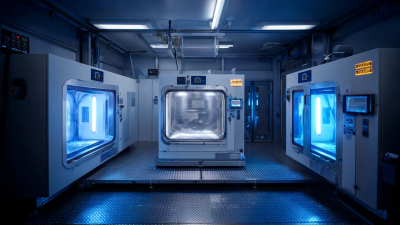

An environmental test chamber is a controlled environment designed for testing various products. These chambers simulate real-world conditions, such as temperature, humidity, and pressure. They help engineers and scientists understand how devices perform under extreme conditions. A small change in temperature can significantly affect results. This can yield mixed findings that require careful interpretation.

Inside the chamber, items are subjected to various cycles of stress. For example, a device might be exposed to high heat followed by low temperatures. It simulates conditions that might occur during shipping or everyday use. Engineers find it critical to analyze how products react. Sometimes, the results are surprising. A product may pass initial tests but fail when conditions change.

The design of these chambers is intricate. They utilize advanced technology to ensure accuracy. However, achieving the perfect environment remains challenging. Small variations can lead to different outcomes. Researchers are often left questioning why results aren’t as expected. This reveals that testing not only checks durability but also encourages reflection on design and manufacturing processes.

Types of Environmental Test Chambers and Their Applications

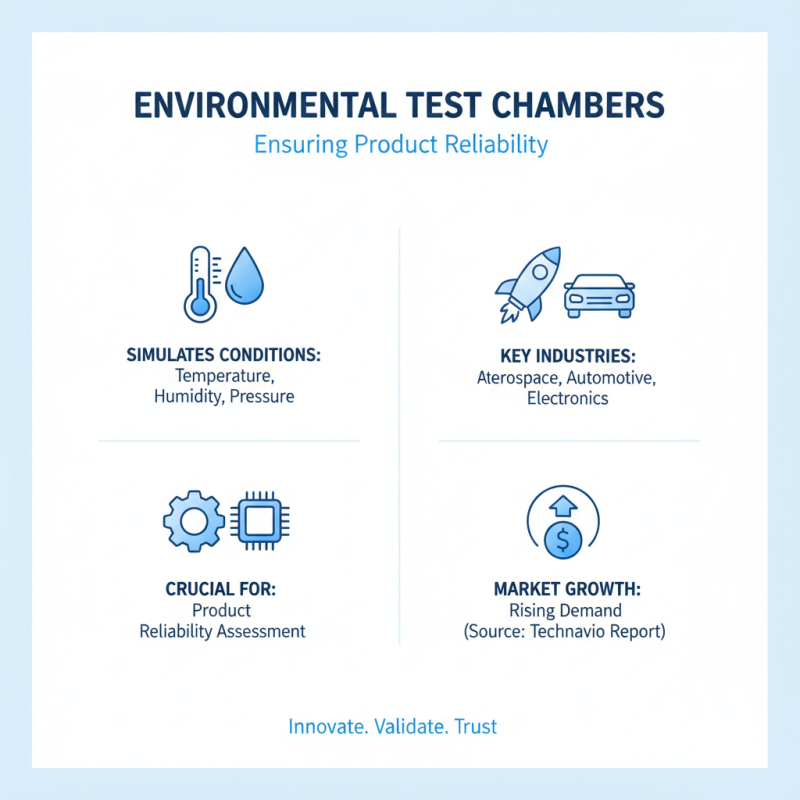

Environmental test chambers play a critical role in testing diverse products under controlled conditions. They simulate various environmental factors such as temperature, humidity, and vibration. Many industries, including electronics and aerospace, rely on these chambers for product development.

There are several types of environmental test chambers. Temperature and humidity chambers are widely used. These chambers can accurately replicate extreme conditions. For instance, some studies show that products tested in these conditions are 30% more reliable than those not subjected to them. Thermal shock chambers are another type. They expose products to rapid temperature changes, ensuring they can withstand harsh environments.

Vibration test chambers assess how products perform under mechanical stress. Approximately 20% of product failures occur during transportation and storage. These tests help identify weaknesses. Moreover, altitude test chambers simulate high-altitude conditions, which is crucial for aerospace applications. The data shows that testing at altitude can prevent 15% of field failures. These chambers are vital, but not all companies utilize them effectively. There is often a gap in understanding their benefits, leading to unreliable product delivery.

How Environmental Test Chambers Function: Key Features

Environmental test chambers are crucial for assessing product reliability under varying conditions. These chambers replicate environmental factors such as temperature, humidity, and pressure. Often, they are used in industries including aerospace and automotive. According to a report by Technavio, the global environmental test chamber market is expected to grow significantly, indicating rising demand for reliable testing solutions.

Key features of these chambers include precise control systems. They allow accurate temperature adjustments from -70°C to +180°C. Humidity control can range from 10% to 98%. These features help simulate real-world conditions. Testing under such circumstances can expose weaknesses in design. For example, studies indicate that 70% of product failures occur due to environmental factors.

However, not all chambers deliver equal performance. Calibration issues can arise. Inadequate insulation or malfunctioning sensors may lead to inaccuracies. These flaws can result in costly rework. A recent study highlighted that 30% of companies face issues due to unreliable testing results. Hence, selecting a quality environmental test chamber is vital for product success.

Factors Influencing Testing Results in Environmental Chambers

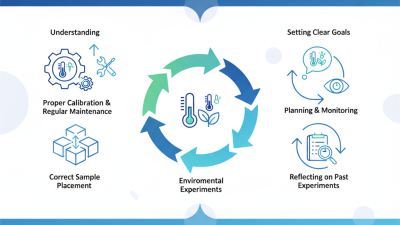

Environmental test chambers are essential for simulating various environmental conditions. However, several factors can influence the testing results within these chambers. Understanding these factors is crucial for accurate assessments.

Temperature fluctuations can significantly impact test outcomes. Chambers must maintain a consistent temperature, but small variations can affect material behavior. Humidity is another critical factor. Changes in moisture levels can alter results, especially for sensitive materials. Additionally, the design of the chamber itself can influence airflow and temperature distribution. Uneven circulation may lead to inconsistent testing conditions.

The size of the samples also matters. Smaller samples might not behave like larger ones. This can create discrepancies in data. Sometimes, it’s easy to overlook these details. Calibration of instruments is vital, too. Inaccurate sensors can lead to faulty readings. Each element must be carefully controlled. Even minor oversights can affect the reliability of the results. Testing in environmental chambers requires meticulous attention to detail. The pursuit of accuracy is ongoing, and reflection on past results can lead to improvements in future testing.

Maintenance and Calibration of Environmental Test Chambers

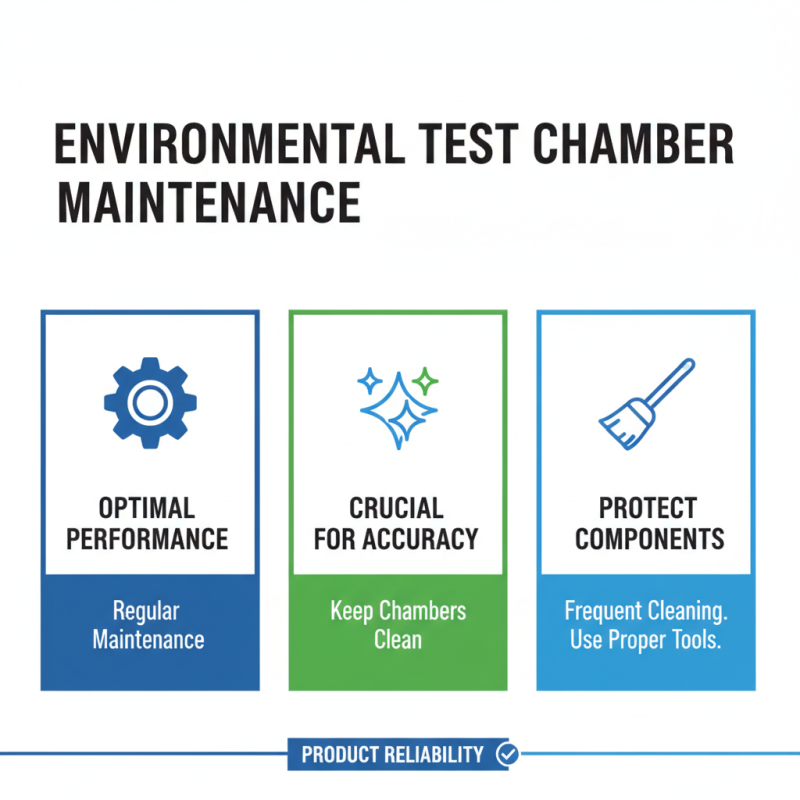

Environmental test chambers play a vital role in product testing. Regular maintenance ensures their optimal performance. Keeping these chambers clean is crucial. Dust and debris can interfere with test results. Cleaning should happen frequently, using proper tools to avoid damaging sensitive components.

Calibration is equally important. It verifies that the chamber operates within specified parameters. Regular checks help detect issues early. Instruments should be calibrated against reliable standards. This process can be overlooked, leading to inaccurate results. Testing conditions can change over time. If not recalibrated, they may deliver misleading data.

Using a logbook for maintenance is beneficial. It tracks when services are performed. This practice encourages accountability and timely interventions. Without proper records, forgetfulness may result in skipped maintenance. Environmental test chambers need attention to detail. Small oversights can lead to significant consequences in testing outcomes.

Related Posts

-

The Ultimate Guide to Choosing the Right Environmental Test Chamber for Your Laboratory Needs

-

Essential Checklist for Selecting the Right Temperature Test Chamber for Your Testing Needs

-

Solutions for Tailored Environmental Test Chamber Applications

-

Exploring the Essential Role of Temperature and Humidity Chambers in Climate Simulation and Testing: A Deep Dive

-

Why is a Test Chamber Essential for Quality Control in Product Development

-

How to Use a Temperature and Humidity Chamber Effectively?

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.