How to Use a Tensile Testing Machine Effectively?

A tensile testing machine is essential for material analysis. It measures how materials react to stress and strain. Understanding its effective use can enhance accuracy and reliability in results.

To begin, ensure proper calibration of the tensile testing machine. This step is crucial for obtaining valid measurements. A slight error may lead to significant discrepancies. Next, sample preparation is key. Properly cut and shaped samples will provide better data. Neglecting this can affect the overall test quality.

While utilizing the tensile testing machine, operators must pay attention. Small issues, such as temperature, can influence outcomes. Always record environmental conditions during tests. Reflecting on these factors can lead to better results and ongoing improvements. Always seek ways to optimize testing procedures. This will ultimately enhance material assessments.

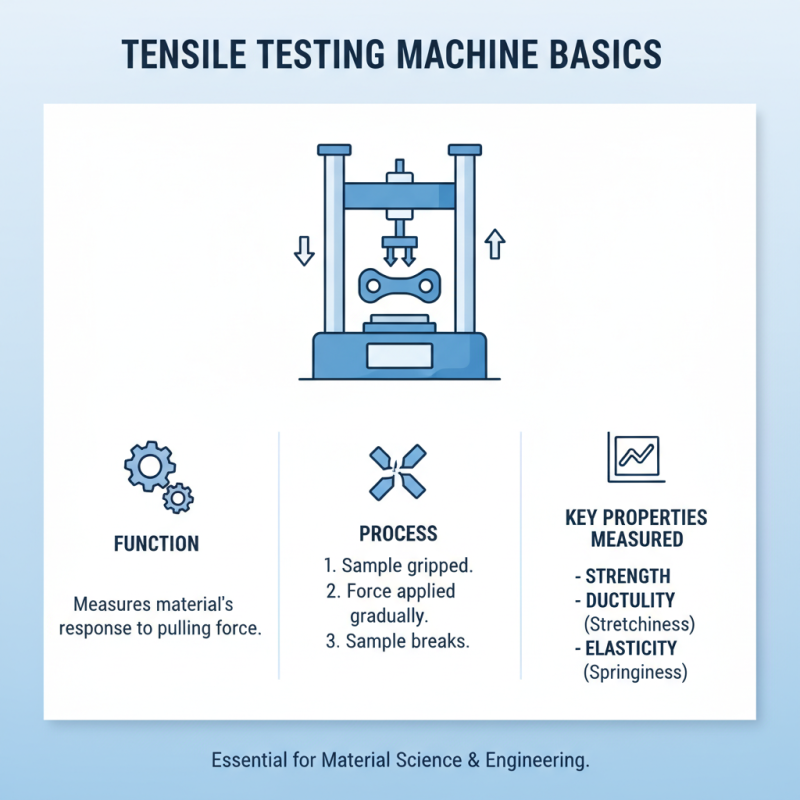

Understanding the Basics of Tensile Testing Machines

Tensile testing machines play a crucial role in material science. They measure how a material reacts to tension. Understanding the basics is essential for effective use. These machines grip samples at both ends and apply a force until they break. This process helps in determining the material’s strength, ductility, and elasticity.

Knowing the specifications is vital. Every machine has different capabilities and limitations. Users must check the machine’s maximum load and sample size. Calibration is another important aspect. An uncalibrated machine can yield incorrect results. Therefore, users should regularly check settings and adjust as needed.

Safety cannot be overlooked. Users must wear protective gear during testing. Unexpected failures might occur, posing risks. Ensure that all personnel understand machine operation. Training is often insufficient, and mistakes can happen. Reflecting on past testing experiences can help improve future practices. Proper documentation of results is necessary. It allows analysis and comparison over time.

Preparing the Sample for Accurate Testing Results

Preparing a sample for tensile testing is crucial for obtaining accurate results. The geometry and size of the sample significantly affect test outcomes. According to a report by the American Society for Testing and Materials (ASTM), variations in sample dimensions can lead to discrepancies of up to 20% in tensile strength results. It's essential to adhere to standardized dimensions for reproducibility.

A clean and controlled environment is also important. Contaminants can alter material properties. A study indicated that even minor surface irregularities could lead to failure at lower stress levels. Proper surface preparation can enhance reliability. It is advisable to follow specific cleaning protocols before testing.

Sample alignment in the testing machine must not be overlooked. Misalignment can introduce errors. Research shows that misaligned samples can skew data by nearly 15%. Regular maintenance of the testing machine ensures that it functions correctly, which is often neglected. Habits of sample preparation require routine reflection to identify areas of improvement.

Material Strength Comparison Using Tensile Testing Machine

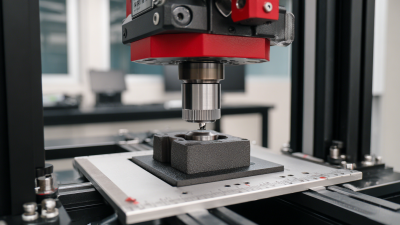

Setting Up the Tensile Testing Machine Properly

Setting up a tensile testing machine properly is crucial for accurate results. Begin by ensuring the machine is on a stable surface to avoid vibration. Check that all components are clean and free of debris. This prevents interference during testing. It's important to inspect the grips. They should be aligned perfectly to avoid misreading the data. If the specimen slips or doesn’t fit well, the results can be flawed.

Next, load the test specimen carefully. Measure its dimensions precisely. Use calipers or micrometers for accuracy. A small error in size can lead to significant deviations in results. Make sure the specimen is centered in the grips. Off-center loading can create unexpected stress points. Adjust the load cell if it requires calibration. It’s a delicate process and often overlooked. Testing outside of the machine's specified range could yield misleading outcomes.

After setup, run a preliminary test. Monitor the machine for any unusual sounds or movements. If something feels off, reevaluate your setup. Rushing this step can lead to frustration. Remember, patience in setup saves time later. Each detail matters. Achieving reliable results goes beyond just following steps; it requires constant reassessment of your methodology.

Interpreting Data and Results from Tensile Tests

Interpreting data from tensile tests is crucial for materials science. After a test, you receive stress-strain curves. These curves provide insights into material behavior under load. It's not just about numbers. Each curve tells a story about the material’s strength and ductility.

Pay attention to key points on the curve. The yield point marks where permanent deformation starts. The ultimate tensile strength indicates the maximum stress the material can withstand. However, interpreting these points can be tricky. Sometimes the data can seem contradictory. It requires careful analysis and reflection. Minor errors in setup can lead to false conclusions.

Don't overlook the importance of testing conditions. Factors like temperature, humidity, and even equipment calibration impact results significantly. If results are inconsistent, it’s worth revisiting your procedure. This is a learning process. Small adjustments can make a big difference. The art of interpretation lies in fostering a critical mindset. Regular practice and attention to detail will enhance your skills.

Maintaining and Calibrating the Testing Equipment Regularly

Regular maintenance and calibration of a tensile testing machine are crucial for accurate results. According to industry reports, about 30% of testing errors stem from equipment issues. Insufficient maintenance can lead to discrepancies in tensile strength measurements. Even minor calibration errors can significantly skew data, affecting material quality assessments.

Calibration should occur on a scheduled basis. The recommended frequency is every six months, but this may vary by usage. Daily checks of operational components, such as load cells and grips, help identify early signs of wear. Small issues can escalate into critical problems if left unaddressed. For instance, a misaligned grip could lead to an unrealistic failure point during testing.

Documentation of maintenance activities is vital. It provides a clear history of the machine's condition. Yet, many laboratories overlook this practice. Inconsistencies in documentation can hinder troubleshooting efforts. Implementing a structured maintenance log can save time and resources. It reinforces accountability and promotes a culture of quality within testing environments. The goal should be to ensure that each test reflects the true properties of the material. Regular maintenance makes a significant difference.

Related Posts

-

Why Investing in a Tensile Tester Can Transform Your Quality Control Process

-

Understanding the Importance of Tensile Tester in Material Strength Analysis

-

Ultimate Guide to Tensile Testing Machines Benefits Features and Applications

-

Essential Guide to Understanding Universal Tensile Testing Machines for Accurate Material Analysis

-

Top Climate Chamber Innovations for Research and Development in 2025

-

Why is a Test Chamber Essential for Quality Control in Product Development

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.