How to Use a Temperature and Humidity Chamber Effectively?

Using a temperature and humidity chamber effectively is essential for various research and industrial applications. These chambers help simulate environmental conditions, allowing for controlled experiments. However, many users miss the mark when utilizing these devices. It is easy to overlook important settings, which can lead to inaccurate results.

Understanding the workings of a temperature and humidity chamber is crucial. Proper calibration is vital. Many users do not frequently check calibration, impacting their experiments. Regular maintenance is often neglected, causing unreliable data. Moreover, incorrect sample placement can affect air circulation, leading to inconsistent results.

Setting clear goals before experimentation is necessary. Users should consider specific temperature and humidity requirements. Yet, many jump into testing without adequate preparation. By planning and monitoring settings during tests, better outcomes are achievable. Reflecting on past experiments helps refine techniques and improve future results.

Understanding the Purpose and Benefits of Temperature and Humidity Chambers

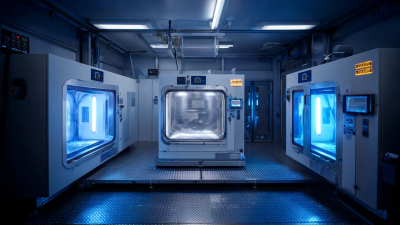

Temperature and humidity chambers play a critical role in various industries. They provide controlled environmental conditions for testing. This ensures products can withstand real-world conditions. According to a report from the Environmental Testing Association, 70% of failures in material testing come from inadequate environmental controls.

These chambers simulate climates, which is essential for research and development. They help manufacturers identify potential issues before production. For example, a study found that 60% of electronic device failures occur due to humidity-related degradation. Such data emphasizes the importance of reliable testing environments. The investment in temperature and humidity chambers can lead to better products and reduced warranty claims.

However, effectively using these chambers requires understanding their limitations. Not all materials respond the same to temperature and humidity variations. Some tests may not mimic real conditions accurately. This can lead researchers to overlook critical failure points. Balancing test accuracy with operational costs remains a challenge for many organizations.

Choosing the Right Temperature and Humidity Chamber for Your Needs

When choosing a temperature and humidity chamber, it’s crucial to understand your specific requirements. Each research or testing application might have different needs. For example, according to a recent market study, 35% of industries require precise control over environmental conditions for product endurance testing. This demand underscores the importance of selecting a chamber that meets those precise specifications.

Consider the size of the chamber. A smaller unit may suffice for basic tests. However, if you plan to scale up your experiments, invest in a larger model. The same market study indicates that 40% of companies faced limitations due to size constraints. Moreover, pay attention to the range of temperature and humidity. Chambers that provide a wider range give flexibility for various tests. One report noted that 25% of unexpected results stemmed from inappropriate environmental conditions.

Reflect on the features you truly need. Some advanced functions may appear appealing but can complicate usage. This can lead to operator error, which 15% of technicians reported in their assessments. Therefore, assess what you will realistically use. Balancing functionality with user-friendliness can avoid unnecessary frustrations down the line.

Setting Up Your Temperature and Humidity Chamber Properly

Setting up a temperature and humidity chamber properly is crucial for accurate results. Start by selecting a suitable location. The chamber should be on a flat, stable surface. Avoid areas with direct sunlight or extreme drafts. Ensure there is enough space around the chamber for ventilation.

Next, calibrate the chamber before use. This step often gets overlooked. A poorly calibrated chamber can lead to misleading results. Use precise sensors to monitor both temperature and humidity. Confirm that these sensors are within the recommended range.

After setup, maintain a routine check. Watch for any fluctuations in readings. Minor adjustments may be required. Sometimes, small errors can lead to significant discrepancies in your experiments. It's essential to keep a record of these checks for future reference. Reflect on any inconsistencies you observe. Learning from these moments can enhance your process over time.

Temperature and Humidity Chamber Data

The following chart displays the relationship between temperature and humidity levels over a week, illustrating ideal settings for effective use of a temperature and humidity chamber.

Monitoring and Maintaining Optimal Conditions in the Chamber

To effectively monitor and maintain optimal conditions in a temperature and humidity chamber, regular checks are crucial. Use reliable sensors to measure temperature and humidity accurately. It is essential to calibrate these sensors periodically. Improper calibration can lead to misleading results. Ideally, strive for stability in your readings.

Adjusting the settings based on your specific requirements is critical. For instance, some experiments may need high humidity, while others require a dry environment. Be cautious with extreme settings. They can lead to equipment stress or failure over time. Always keep an eye on fluctuations and respond accordingly.

Sometimes, equipment malfunctions can occur unexpectedly. When this happens, assess both the chamber and the sensors. Look for leaks or any signs of wear and tear. Documenting these issues can help prevent future problems. Regular maintenance is essential to extend the lifespan of your chamber. Small oversights today can lead to significant challenges tomorrow.

How to Use a Temperature and Humidity Chamber Effectively? - Monitoring and Maintaining Optimal Conditions in the Chamber

| Condition | Optimal Range | Monitoring Frequency | Adjustment Method |

|---|---|---|---|

| Temperature | 20°C - 25°C | Every 30 minutes | Adjust thermostat |

| Humidity | 40% - 60% | Every hour | Use humidifier or dehumidifier |

| Air Flow Rate | 500 - 1000 m³/h | Daily | Adjust fan speed |

| Light Intensity | 200 - 400 µmol/m²/s | Every week | Adjust light fixtures |

Interpreting Results and Making Adjustments for Accurate Testing

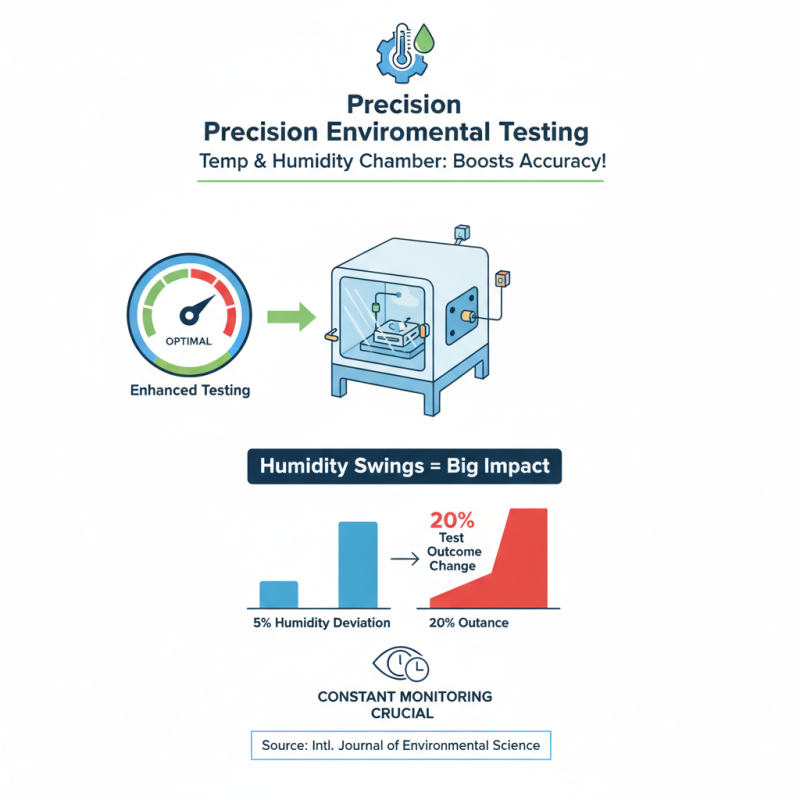

Using a temperature and humidity chamber can greatly enhance testing accuracy. However, interpreting results may be challenging. For example, humidity levels can fluctuate significantly. According to a recent study by the International Journal of Environmental Science, a 5% deviation in humidity can lead to a 20% change in test outcomes. This highlights the need for continuous monitoring during experiments.

Adjustments are crucial for reliable testing. Calibration of sensors must be done regularly to avoid errors. Not all chambers maintain consistent climates, which can lead to unexpected variances. An alarming 30% of devices fail to meet industry standards for precise temperature and humidity control. Understanding how to calibrate these devices is essential for effective usage.

Testing protocols should also take into account the materials being assessed. Different materials react uniquely to temperature and humidity changes. For instance, certain plastics can warp at specific humidity levels. This requires careful planning. Observing where things go wrong is vital. Gathering qualitative data can help refine methodologies for future tests. Addressing these imperfections leads to more reliable results.

Related Posts

-

Top Climate Chamber Innovations for Research and Development in 2025

-

Solutions for Tailored Environmental Test Chamber Applications

-

Choosing the Right Temperature Humidity Chamber: A Comprehensive Comparison Guide

-

How to Choose the Right Temperature Humidity Chamber for Your Specific Testing Needs

-

Exploring the Essential Role of Temperature and Humidity Chambers in Climate Simulation and Testing: A Deep Dive

-

The Ultimate Guide to Choosing the Right Environmental Test Chamber for Your Laboratory Needs

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.