How to Choose the Right Thermal Test Chamber for Your Needs?

Choosing the right thermal test chamber is crucial for various industries. The performance of components often depends on precise thermal testing. According to a recent report from the Thermal Testing Institute, around 72% of product failures occur due to inadequate temperature simulation.

Dr. Lisa Thompson, an expert in thermal dynamics, emphasizes, "A well-chosen thermal test chamber can save both time and money." Companies must consider specific requirements. Different applications demand different temperature ranges and control accuracies. This means that one size does not fit all.

Misunderstanding the needs can lead to poor choices. Some chambers may deliver excessive capabilities, while others fall short. It is essential to reflect on your specific applications and requirements before making a decision.

Understanding Thermal Test Chambers and Their Applications

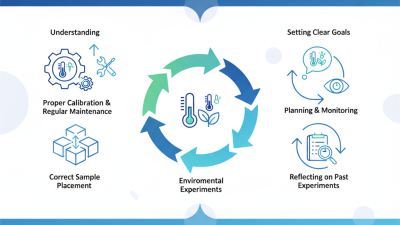

Thermal test chambers are essential tools in various industries. They simulate extreme temperatures and conditions to evaluate product performance. These chambers serve different purposes, from testing electronics to assessing materials. Understanding how they function can guide you in selecting the right one.

Applications for thermal test chambers vary greatly. In aerospace, they ensure components can withstand harsh environments. In automotive, they simulate real-life conditions for parts testing. Researchers rely on these chambers for experimenting with materials. It’s crucial to consider your specific requirements. Many options may not cater to all testing needs.

Selecting the proper thermal test chamber can be challenging. Each specification matters; size, temperature range, and control precision are key. Misalignment with your needs can lead to ineffective testing. Evaluate your application thoroughly. Seek clarity on what environment you require for accurate results. Sometimes, deeper research is needed before finalizing your decision.

Key Factors to Consider When Choosing a Thermal Test Chamber

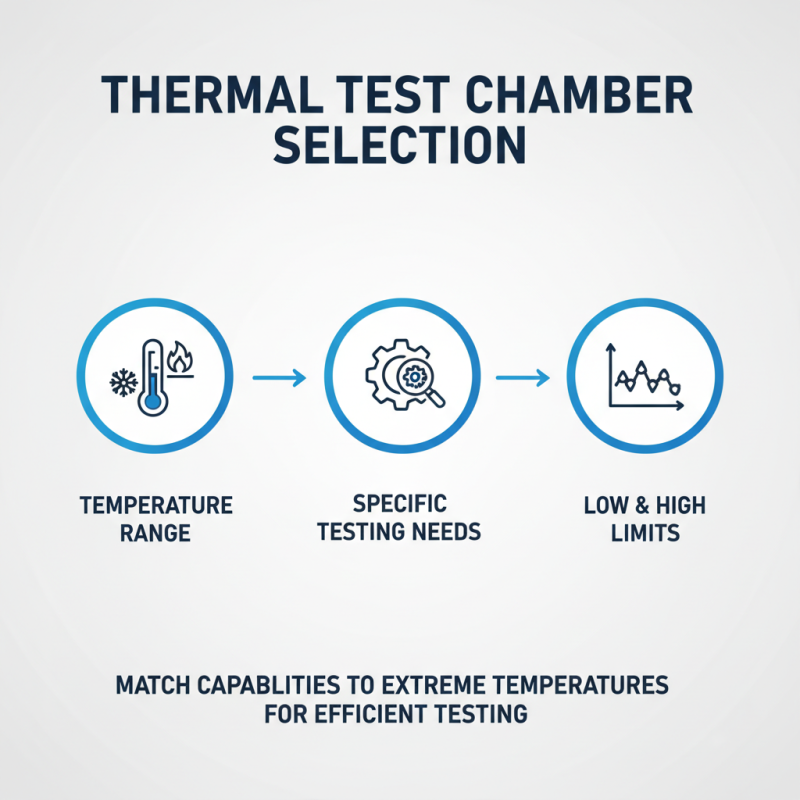

When choosing a thermal test chamber, consider temperature range. The chamber's capabilities must suit your specific testing needs. If you require extreme temperatures, choose a model that reaches them efficiently. Remember, low and high limits impact your tests significantly.

Another crucial factor is size. Assess your samples and how much space you need. A smaller chamber might save costs, but it could limit your testing capabilities. Ensure there's sufficient room for airflow and heat distribution. This can affect test accuracy.

Tips: Always check the insulation quality. Poor insulation can lead to energy loss and skew results. Also, consider the ease of use. Is the interface intuitive? Complicated setups can lead to errors and wasted time. Finally, review maintenance requirements. Neglecting upkeep can result in costly repairs or compromised tests. Choose wisely to avoid future issues.

Types of Thermal Test Chambers and Their Specific Uses

When selecting a thermal test chamber, it’s essential to understand the various types available. Environmental test chambers come in many forms, including temperature chambers, humidity chambers, and thermal shock chambers. Each type serves specific industries and applications. Temperature chambers are perfect for testing products in extreme heat or cold. Humidity chambers help evaluate how products respond to moisture levels, simulating real-world conditions.

Thermal shock chambers offer quick shifts between extreme temperatures. They test durability and performance qualities. These chambers are crucial for industries like electronics, automotive, and aerospace. Choosing the right type must align with your testing goals and product requirements.

**Tip:** Consider the size of your samples. A chamber too small may limit effectiveness. Ensure it accommodates your products comfortably.

It’s also vital to think about the temperature range you need. Some chambers offer wider ranges than others. This can impact your testing. Evaluate long-term reliability and maintenance needs as well. Sometimes, cheaper options require more upkeep, leading to future challenges.

**Tip:** Always check for energy efficiency. An efficient chamber saves costs in the long run.

Evaluating Performance Specifications and Features

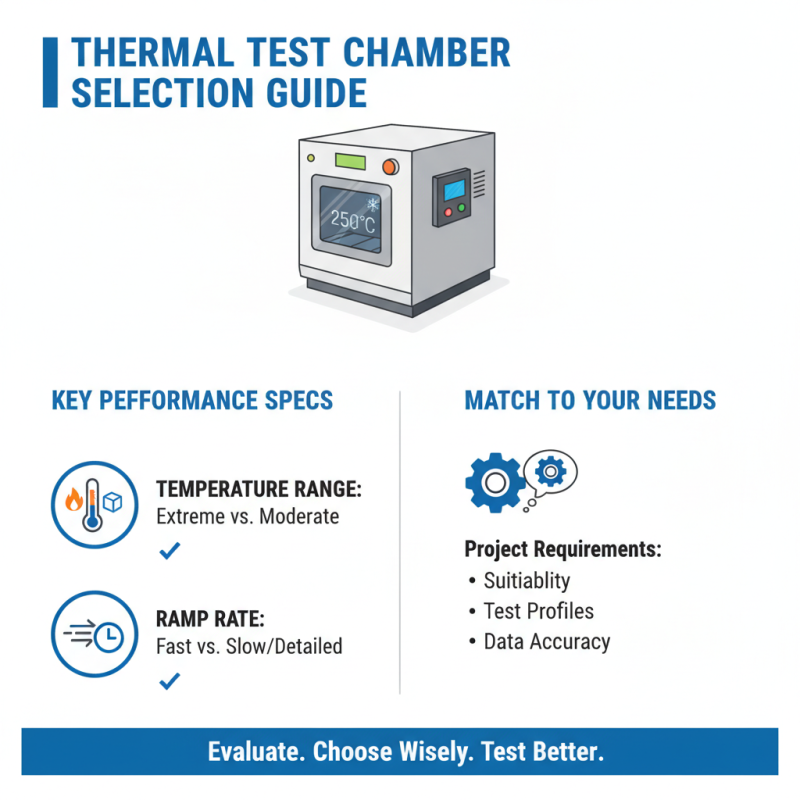

When choosing a thermal test chamber, evaluating performance specifications is crucial. The temperature range, for instance, is a primary factor. Ensure it suits your testing needs. Some projects require extreme temperatures, while others operate in moderate ranges. Consider the ramp rate too. A faster rate may be needed for some tests, but a slow, detailed approach works better for others.

Look closely at the chamber’s interior dimensions. Larger samples need space. Small dimensions may limit your work. Additionally, check for uniformity within the chamber. Inconsistent temperatures can lead to faulty results, causing frustration and wasted resources. Pay attention to features like data logging and user interfaces. They can enhance or hinder your workflow.

Reflect on your existing processes and ask if the chamber fits well within them. Sometimes additional capabilities are attractive, but they may complicate usage. Forgetting to test the chamber's efficiency can lead to regrets. Assess features carefully against your real needs. The right balance will ultimately save time and ensure accurate results in your projects.

Budgeting and Cost Considerations for Thermal Test Chambers

When budgeting for a thermal test chamber, understanding the costs involved is crucial. Basic models can start around $5,000, while high-end chambers exceed $30,000. The price gap reflects features like temperature range, size, and control precision. According to industry reports, around 70% of purchase decisions hinge on these specifications.

Consider additional expenses. Installation may add 10-15% to the initial cost. Calibration is often necessary every year, costing about $1,000. Maintenance fees can accumulate, too. Neglecting these could lead to performance issues. It's important to allocate funds for both expected and unexpected costs.

The longevity of the equipment is another factor. A well-maintained chamber can last a decade or more, providing a strong return on investment. However, short-term savings by choosing cheaper models might lead to long-term challenges. A thermal test chamber should serve your needs efficiently and effectively. Be aware of your specific requirements before making a final choice.

Related Posts

-

Why is a Test Chamber Essential for Quality Control in Product Development

-

7 Compelling Reasons to Invest in Thermal Chambers for Your Business Success

-

Top Climate Chamber Innovations for Research and Development in 2025

-

Top 10 Temperature Humidity Chamber Best Practices for Optimal Testing

-

How to Use a Temperature and Humidity Chamber Effectively?

-

Ultimate Guide to Tensile Testing Machines Benefits Features and Applications

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.