How to Choose the Right Temperature Chamber for Your Laboratory Needs

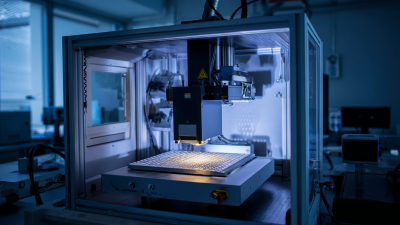

When it comes to conducting precise experiments in a laboratory setting, selecting the right equipment is crucial for obtaining reliable results. One essential piece of equipment that often goes overlooked is the temperature chamber. These chambers play a vital role in various applications, including material testing, pharmaceutical research, and biological studies, as they provide controlled environments for temperature-sensitive experiments. However, with the market offering a plethora of options, choosing the most suitable temperature chamber for your laboratory needs can be a daunting task.

In this guide, we will explore critical factors to consider when selecting a temperature chamber, ensuring that your laboratory has the necessary tools to produce accurate and reproducible results. Understanding the specifications, such as temperature range, uniformity, and dimensions, is key in determining which chamber will best accommodate your specific research needs. Additionally, we'll address the importance of considering the type of experiments you conduct and how they influence your choice of temperature chamber. By the end of this guide, you will have the knowledge and confidence to make an informed decision that aligns with your laboratory's objectives.

Understanding Temperature Chamber Types: Key Features and Functions

When selecting a temperature chamber for your laboratory, understanding the types and functionalities available is essential for making an informed decision.

Temperature chambers can be broadly categorized into environmental test chambers, stability chambers, and thermal shock chambers, each serving distinct purposes.

According to a report by Research and Markets, the global temperature chamber market is projected to reach $1.5 billion by 2025, highlighting the growing demand for precise temperature control in research and quality assurance across various industries.

Environmental chambers are ideal for simulating different environmental conditions, allowing scientists to test how products respond to temperature, humidity, and light.

Stability chambers, on the other hand, are tailored for long-term storage of pharmaceuticals, providing controlled environments that comply with regulatory requirements.

Thermal shock chambers test materials' resilience to rapid temperature changes, crucial for sectors like aerospace and automotive.

Tip: Always consider the chamber's temperature range and uniformity specifications, as these factors significantly affect experimental accuracy.

Additionally, look for features such as data logging and remote monitoring capabilities to enhance your laboratory's efficiency and compliance.

Evaluating Size and Capacity: Matching Your Laboratory Requirements

When selecting the right temperature chamber for your laboratory, evaluating size and capacity is crucial to match your specific requirements. The dimensions of the chamber must correspond to the volume of samples you intend to store or test. It is important to consider both the physical dimensions and the interior layout to ensure seamless workflow and accessibility. A chamber that is too small may lead to overcrowding, which can compromise temperature uniformity, while an excessively large chamber may result in inefficient energy consumption.

Additionally, understanding the capacity needed for your laboratory will guide you in choosing a chamber that meets your operational demands. For instance, if your laboratory frequently engages in varied experiments requiring different temperature settings, opt for a chamber with flexible capacity solutions that can accommodate these fluctuations. This adaptability is similar to how portable power stations are designed to meet diverse power requirements, providing a versatile approach to energy needs. By aligning the chamber's capacity with your lab’s workload and specific projects, you can ensure optimal performance and durability.

Key Specifications to Consider: Temperature Range and Stability

When selecting a temperature chamber for your laboratory, the temperature range and stability are crucial specifications to consider. The temperature range refers to the minimum and maximum temperatures the chamber can achieve, which should align with your specific experimental requirements. For instance, if your research involves storing samples at ultra-low temperatures, you'll need a chamber with a range that extends far below freezing. Conversely, for applications involving high-temperature testing, ensure the chamber can reach the necessary elevated temperatures without compromising its integrity or your samples.

Additionally, temperature stability is essential for reliable results in laboratory work. A chamber with superior stability will maintain a consistent temperature level, minimizing fluctuations that could lead to experimental variability. Look for units that offer tight tolerances and rapid recovery times after door openings or when external conditions change. Investing in a temperature chamber that excels in both range and stability guarantees that your laboratory will meet stringent testing demands, providing confidence in the accuracy and reproducibility of your research outcomes.

Energy Efficiency and Operating Costs: Balancing Performance and Budget

When selecting a temperature chamber for laboratory applications, it is essential to consider not only performance but also energy efficiency and operating costs. According to the U.S. Department of Energy, energy-efficient laboratory equipment can reduce energy consumption by up to 30%. For temperature chambers, this translates to significant savings over time, especially in facilities that operate continuously or have extensive testing schedules. By investing in models that utilize advanced insulation and energy-efficient compressors, laboratories can enhance their operational sustainability while reducing expenditure.

Operating costs vary significantly depending on the chamber's design and energy consumption. A comprehensive report by the ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) stated that the energy cost can account for more than 50% of the total operating costs of laboratory equipment. Therefore, selecting a chamber that is rated for lower kilowatt hours per cubic foot can lead to improved long-term cost-efficiency. Additionally, many modern chambers are equipped with smart technology that optimizes energy use, allowing users to achieve desired temperature control without excessive energy draw, ensuring that both performance and budgetary constraints are balanced effectively.

Energy Efficiency and Operating Costs of Temperature Chambers

Choosing Between Standard and Customized Solutions for Enhanced Performance

Choosing the right temperature chamber for your laboratory can significantly impact the accuracy and reliability of your experiments. When deciding between standard and customized solutions, it's essential to consider your specific research requirements. Standard temperature chambers may suffice for routine testing, offering predefined temperature ranges and humidity controls that meet general laboratory standards. However, for specialized applications, customized chambers can be tailored to meet precise specifications, ensuring optimal performance and results.

Tips: When opting for a customized solution, closely evaluate the unique parameters of your experiments, such as temperature range, volume, and any additional features. Engage in dialogue with manufacturers to discuss potential modifications that could better serve your needs.

Selecting the right chamber also requires careful consideration of operational costs. Customized chambers can be more expensive upfront, but their increased efficiency and effectiveness often lead to cost savings in the long run. Therefore, analyze not just the initial investment but also how the chamber's capabilities will enhance your overall laboratory productivity and outcomes.

Tips: Perform a cost-benefit analysis that factors in potential downtime and error rates with standard models versus the reliability of customized units. Regular maintenance and calibration should also be considered when making your choice to ensure longevity and optimal functionality.

Related Posts

-

Essential Checklist for Selecting the Right Temperature Test Chamber for Your Testing Needs

-

Solutions for Tailored Environmental Test Chamber Applications

-

Ultimate Guide to Understanding Thermal Chambers: Selection, Usage, and Best Practices

-

How to Choose the Right Thermal Test Chamber for Your Product Development Needs

-

Exploring the Essential Role of Temperature and Humidity Chambers in Climate Simulation and Testing: A Deep Dive

-

Exploring the Role of Climatic Test Chambers at the 138th Canton Fair 2025 in China's Testing Industry

Have Questions? We're Here to Help!

Give us a call at (864) 989-0566 or send us a message to discuss our testing equipment with an expert.